Pellet Snacks Production Line Manufacturer

Inflate Production Line, puffed food (extruded food) Production Line, inflated food Production Line, snack pellets Production Line, cracker Production Line, pellet snacks frying production line, pellet production line, snack food manufacturing

As the global snack food market continues to expand, snack manufacturers face a critical challenge: how to maintain consistent texture, appearance, and product quality while operating high-capacity, continuous production lines. Pellet snacks are typically produced from low-moisture raw materials such as grains, potatoes, and legumes, which require precise pressure and heat to expand properly during frying. Without stable process control, fluctuations in oil temperature can lead to uneven expansion, inconsistent texture, and quality variation, directly affecting production yield and operational efficiency.

How the Pellet Snacks Frying Production Line Solves These Challenges

The pellet snacks frying production line is designed to address these challenges by providing stable, continuous frying performance for industrial snack food manufacturing. Through a continuous fryer system with precise oil temperature control, the production process maintains consistent frying conditions, ensuring uniform expansion, crisp texture, and reliable product quality. This makes the pellet production line particularly suitable for large-scale, continuous snack food processing, helping manufacturers meet growing market demand with confidence.

Pellet Production Line for Industrial Snack Manufacturing

The pellet production line offers a high-efficiency and automated processing solution for snack manufacturers, widely applied in the continuous frying of 2D and 3D expanded pellet snacks. By integrating a continuous fryer, conveying system, seasoning equipment, oil circulation, and temperature control, this pellet snacks frying production line delivers consistent expansion performance, texture, and appearance across a wide range of pellet snack products, including potato-based, grain-based, and multi-ingredient pellets.

Process Characteristics & Production Benefits

Focused on stable process control and reliable mass-production performance, the pellet snacks frying production line is suitable for existing food factories, equipment upgrades, or newly established production lines. The continuous frying design effectively maintains stable oil temperature throughout operation, minimizing quality fluctuations caused by temperature variation. As a result, snack food factories can achieve higher production yield, improved line efficiency, and consistent long-term operation in industrial snack food production environments.

Features Of Fish Shred Production Line

1. Having porous and fluffy texture, delicate shape, nutritious, crisp and delicious, and has certain nutritional value.

2. Automatic production line.

3. Various shape product available to meet market requirement.

4. Products can be fried, be pan-fried, and can be adjusted according to local taste.

5. Both fried and roasted processing are available according to need.

6. Manpower economizing

7. Both semi-finished and finished products can be sold.

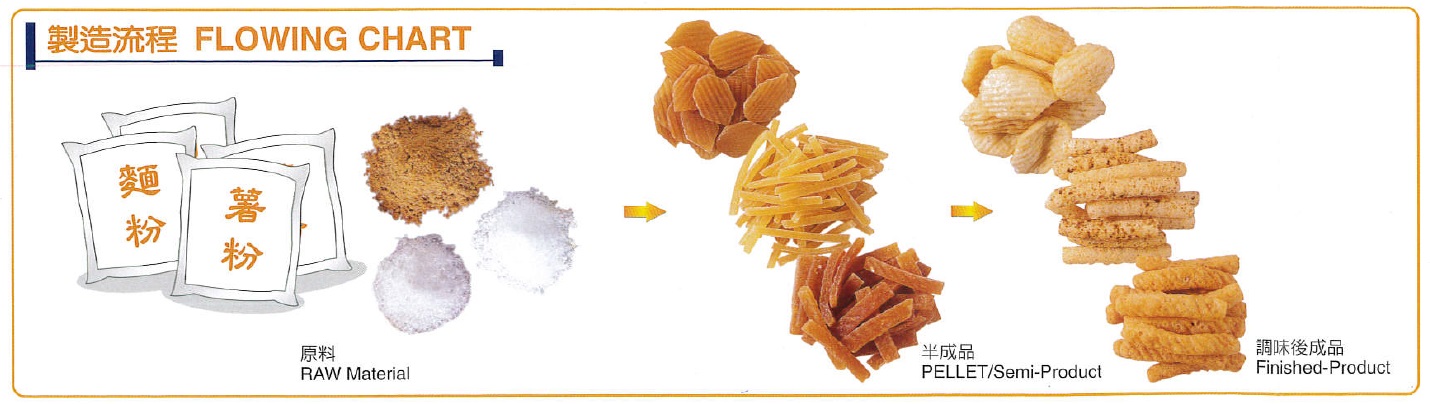

Process

First Semi-Products:

Raw material→Steam kneading→Dough laminate→Cooling conveyor→Cooling room→Cutting→1st dryer

Second Finished Products:

2nd dryer→Frying or roasting→Seasoning→Drying→Packing

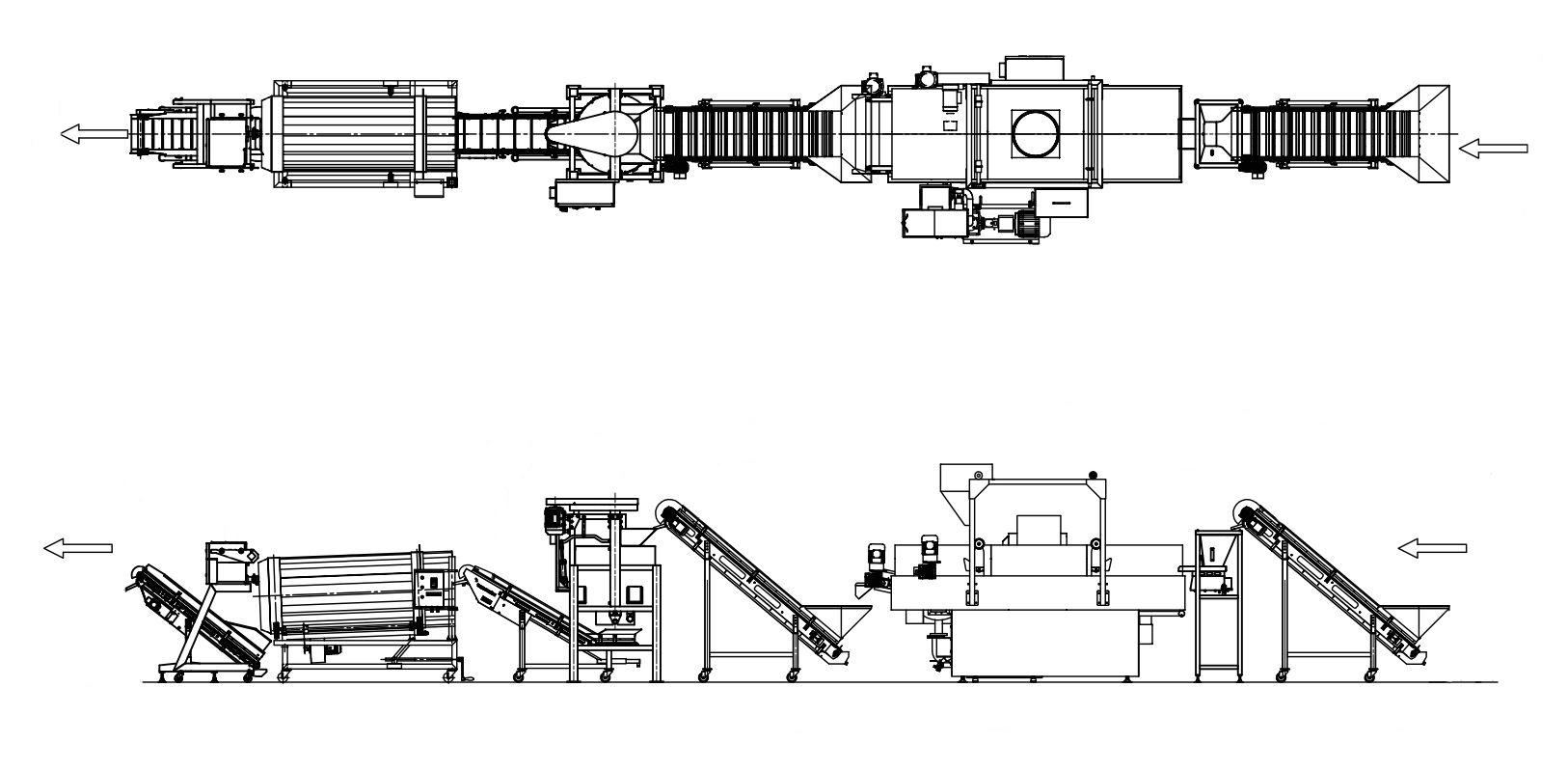

Machine Layout

Equipment Information of Pellet Snacks Production Line

The pellet snacks production line consists of a series of key processing equipment designed to ensure stable quality and high-efficiency continuous production of expanded pellet snacks. The process begins with a conveyor, which transfers raw materials smoothly to the front-end system, followed by a vibratory feeder that delivers uniform and consistent feeding. The pellets then enter the core equipment—the continuous deep oil fryer, where controlled frying temperature and time enable proper expansion and frying performance. After frying, excess surface oil is removed by the vibratory de-oiling unit, and the product proceeds to the flavor sprinkler and seasoning drum for even and consistent seasoning application. Finally, the seasoned pellet snacks are transferred by the discharge conveyor to downstream cooling or packaging processes, forming a complete and reliable industrial pellet snacks frying production line.

The machine specifications will be adjusted according to product requirements. Please refer to the official quotation provided by our sales department for the final quote.

1. Conveyor to Vibratory Feeder

In the front-end section of the pellet snacks production line, the conveyor to vibratory feeder is designed to deliver pellet materials steadily and continuously into the frying system. The unit is equipped with a hopper to properly receive raw materials and ensure smooth feeding. A food-grade PP belt is adopted to meet food processing hygiene standards, while belt partitions are installed to control the feeding rate and maintain consistent material flow. The equipment measures L2500 × W870 × H2000 mm, with an effective conveyor width of 400 mm, and requires 1/2 HP power. This configuration provides stable and reliable feeding performance, supporting continuous operation and ensuring consistent upstream supply for the pellet snacks frying production line.

2. Vibratory Feeder

In the pellet snacks production line, the vibratory feeder is designed to feed pellet products evenly and consistently into the continuous fryer through controlled vibration. This feeding method helps regulate the feeding rate and distribution, ensuring a uniform product flow before frying and preventing uneven expansion or frying quality issues. The unit is equipped with a hopper with an approximate capacity of 85 liters and a hopper width of 650 mm, making it suitable for continuous pellet snacks frying operations. With an overall size of L1145 × W1060 × H1610 mm and a power requirement of 2.2 kW, the vibratory feeder provides stable and reliable feeding performance for long-hour industrial snack food production.

3. Continuous Deep Oil Fryer

The continuous deep oil fryer is the core equipment of the pellet snacks production line, specifically designed for continuous frying of expanded pellet snacks. Model FRYIN-302-E-S is constructed entirely of food-grade SUS 304 stainless steel, including the heating tubes, ensuring hygiene compliance and long-term durability. The machine measures L3500 × W2350 × H1950 mm, with a frying space of L2500 × W820 × H50 mm, and holds approximately 440 liters of oil, making it suitable for medium- to high-capacity snack food production.

Featuring an internal heating chamber, the fryer is designed to optimize space utilization while reducing oil consumption and energy usage. An automatic oil level control system maintains stable frying conditions, while the single-layer mesh conveyor with inverter control allows flexible adjustment of frying time and conveyor speed to achieve consistent expansion and product quality. The fryer hood is lifted by a screw rod mechanism with upper and lower limit controls, ensuring safe and convenient operation.

4. Vibratory De-Oiling Conveyor

In the pellet snacks production line, the vibratory de-oiling conveyor is designed to effectively remove excess surface oil from pellet snacks after frying, improving product quality and texture consistency. Using a vibratory conveying mechanism, the pellets are gently agitated and flipped during transfer, allowing oil to drain efficiently. The unit measures L1800 × W1000 × H1200 mm, requires 1 HP power, and features adjustable vibration speed to accommodate different pellet snack characteristics.

Constructed entirely of SUS 304 stainless steel, the de-oiling conveyor complies with food processing hygiene standards. A collection tray beneath the mesh belt is provided to gather oil, water, and frying fines, helping maintain a clean production environment. The system consists of two connected vibratory conveyors with a height difference, enabling product flipping during transfer and enhancing de-oiling performance, making it an essential component of the pellet snacks frying production line before seasoning and packaging.

5. Flavor Sprinkler

In the seasoning section of the pellet snacks production line, the flavor sprinkler is designed to evenly and consistently apply powdered seasoning to the surface of pellet snacks, ensuring uniform flavor distribution. Model WJ-001 features a stainless steel construction that meets food processing hygiene standards and is equipped with a 30-liter flavor hopper, making it suitable for continuous pellet snacks frying and seasoning operations. The unit measures L1565 × W619 × H1442 mm and requires 1/4 HP power, providing reliable performance for continuous production.

The flavor sprinkler offers adjustable flavor feeding speed and sprinkling quantity, allowing precise control of seasoning dosage to match different pellet snack products and flavor profiles. With stable and controllable powder application, this system effectively supports downstream seasoning processes and enhances overall seasoning consistency and product quality within the pellet snacks production line.

6. Seasoning Drum

In the seasoning stage of the pellet snacks production line, the seasoning drum is designed to thoroughly mix pellet snacks with seasoning, ensuring uniform flavor distribution and consistent product quality. Model WJ-002 features a stainless steel construction that complies with food processing hygiene standards and is suitable for continuous seasoning operations of expanded pellet snacks. The machine measures L2208 × W1275 × H1677 mm, with a drum diameter of 776 mm, and requires 1/2 HP power, supporting stable continuous production.

The seasoning drum is equipped with adjustable drum inclination and rotation speed, allowing precise control over product tumbling time and mixing intensity according to different pellet snack shapes, densities, and seasoning requirements. By providing controlled and consistent seasoning performance, this equipment works seamlessly with the flavor sprinkler to enhance overall seasoning efficiency and product consistency within the pellet snacks frying production line.

7. Discharge Conveyor

In the downstream section of the pellet snacks production line, the discharge conveyor is designed to smoothly transfer seasoned pellet snacks to subsequent cooling or packaging processes, ensuring uninterrupted line operation. A food-grade belt conveyor is adopted to comply with food processing hygiene standards, with a conveyor width of 400 mm, making it suitable for continuous discharge after frying and seasoning. The machine measures L2000 × W800 × H800 mm and requires 1/2 HP power, providing stable and reliable conveying performance during long-hour operation.

Designed for smooth and continuous product handling, the discharge conveyor helps prevent product accumulation or damage, enabling efficient downstream processing and enhancing overall productivity of the pellet snacks frying production line.

Capacity

- 200kg/hr(FRYIN302)

- 300kg/hr(FRYIN-402)

- 450kg/hr(FRYIN-602)

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machinery manufacturer and supplier of pellet snacks production lines. From raw material, cutting and forming, drying, frying, seasoning, we can provide complete 2D/3D inflate pellet production line solutions.

If you have a Pellet Snacks production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

As the global snack food market continues to expand, snack manufacturers face a critical challenge:...

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

The banana chips production line can be flexibly configured according to different product...

Details- Videos

- Finished Product Gallery

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Pellet Snacks Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Pellet Snacks Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.