Banana Chips Production Line Manufacturer

We provide complete Banana Chips Production Line and Plantain Chips Production Line equipment for processing bananas into slices, frying, and seasoning. The production line integrates automatic slicing, continuous frying, and precision seasoning technologies to ensure efficient production, uniform texture, and consistent product quality. Designed for agricultural processing operations and industrial snack manufacturing, our equipment delivers high-capacity performance and reliable turnkey solutions for banana chip production.

The banana chips production line can be flexibly configured according to different product positioning and capacity requirements, supporting large-scale production of salted, sweet, or others flavored banana chips. The production machine focuses on stable oil temperature control, uniform frying, and effective oil reduction, and can be integrated with automatic seasoning and downstream packaging equipment to form a complete banana chips processing workflow. It is widely applied in Asia, Southeast Asia, and global banana processing markets, meeting manufacturers’ demands for efficiency, food safety, and stable product quality. It is especially suitable for banana-producing countries, snack food manufacturers, emerging food brands, and export-oriented factories, helping businesses enhance automation, reduce labor costs, and strengthen global market competitiveness.

TSHS provides customized solutions for banana chip production lines, from individual machines to complete turnkey line planning. By integrating a continuous frying system with precise temperature control, the solution ensures uniform heat distribution, resulting in consistent color and crispy texture. Combined with de-oiling conveyors and automatic seasoning systems, oil content is reduced while flavor adhesion remains stable. The entire line is constructed with food-grade stainless steel, meeting international food safety standards, and can adjust production capacity according to the market demand of different countries, and help customers build automated, efficient and sustainable TSHS provides customized solutions for banana chip production lines, from individual machines to complete turnkey line planning. By integrating a continuous frying system with precise temperature control, the solution ensures uniform heat distribution, resulting in consistent color and crispy texture. Combined with de-oiling conveyors and automatic seasoning systems, oil content is reduced while flavor adhesion remains stable. The entire line is constructed with food-grade stainless steel, meeting international food safety standards, and can adjust production capacity according to the market demand of different countries, and help customers build automated, efficient and sustainable banana chip food production lines.

After being peeled, the banana will be sticky due to the feature of itself. Therefore, after peeling, it needs to be washed and then sliced. Generally, the slice thickness ranges are from 3 to 5 mm. Different slicers can be used optionally according to customers' needs. The banana is sliced, it can become semi-finished banana chips. After frying, it can optimize the aroma of the banana chips and make it taste crispy.

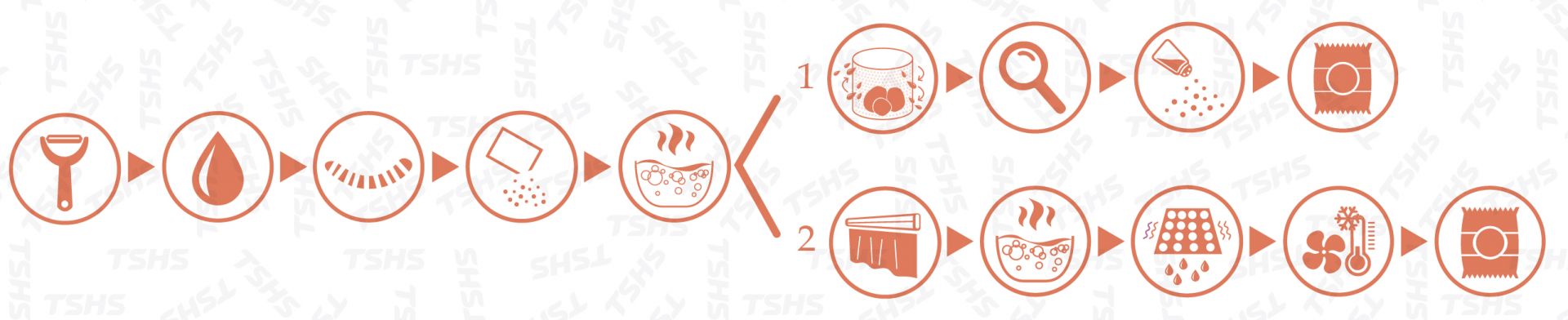

After frying, different seasonings can be made according to the needs of the customer's market. The following can be divided into the following two types:

1. Customers may just need the simple seasoning powder to taste, it is recommended to use the flavor powder sprinkler, the liquid sprayer and the rotary seasoning drum to make the seasoning powder fully adhere to the product.

2. Customers can also screen the fried banana chips first, then wrap the fried banana slices in sugar, and then fry the second time to obtain the fried banana chips.

Features Of Banana Chips Production Line

1. Raw materials are easy to getting: Green bananas are more suitable for production, and production conditions vary depending on the region.

2. No need for complicated procedures: After peeling, washing and cutting → frying → seasoning, it can be packaged for sale.

3. It's easy to control and economize manpower by automatic production.

4. The finished products have stable quality and meet the requirements of food hygiene regulations from integrated production.

Process

Peeling → Washing → Slicing → Quantitative Feeding → Frying→ De-oiling → Screening → Seasoning → Packing

Peeling → Washing → Slicing → Quantitative Feeding → Frying→Syrup Coating→Fryimg→De-oiling→Cooling→Packing

(This is the basic configuration, please contact us for other special processes.)

Equipment Information of Banana Chips Production Line

The banana chips production line is composed of a series of key machines integrated in sequence. The process begins with a Japan Slicer, which ensures uniform slicing thickness to establish a stable foundation for consistent frying quality. Sliced bananas are then transferred via a conveyor system into the Continuous Oil Fryer, where precise temperature control delivers even and reliable frying results. After frying, products pass through a Vibratory De-oiling Conveyor to effectively reduce surface oil content and enhance crisp texture, followed by a Q.C. Conveyor for manual or visual inspection to ensure product consistency. The downstream process integrates a Flavor Sprinkler and a Seasoning Drum to achieve uniform seasoning adhesion, and finally Discharge Conveyor connects seamlessly to packaging or further processing equipment, forming an efficient, automated, and food-safety-compliant banana chips production line.

The machine specifications will be adjusted according to product requirements. Please refer to the official quotation provided by our sales department for the final quote.

1. Japan Slicer

Industrial Japan Slicer for Banana Chips Production Line. The Slicer designed to ensure consistent slicing quality for industrial banana processing. It supports deliver precise cutting thicknesses ranging from 1.0 to 3.0 mm, enabling uniform heat distribution during frying and enhancing final product color consistency and crispness. Powered by a 3-phase 200V, 750W motor, the slicer provides stable and reliable operation suitable for continuous production. With a compact structure and user-friendly operation, the machine is supplied with one cutter set and two knives, allowing flexible integration into various banana chips processing lines for medium- to large-scale manufacturing plants.

2. Conveyor to Continuous Oil Fryer

The conveyor responsible for delivering sliced bananas into the continuous fryer at a stable and controlled feeding rate. This ensures uninterrupted frying operations and consistent product quality. The conveyor is equipped with a food-grade plastic belt and quantitative feeding separators, allowing precise control of product flow while preventing material overlap or uneven loading that could affect frying performance. Built with a stainless steel frame, the system offers durability and easy sanitation. Driven by a 1/2 HP motor, it provides reliable conveying performance and is well suited for medium- to large-scale banana chips processing lines, enhancing overall frying efficiency and line stability.

3. Continuous Deep Oil Fryer

The continuous oil fryer is the core machine in a banana chips production line, directly affecting product crispness, color consistency, and overall production capacity. Model 603 E-D features a large oil capacity and a spacious frying area, enabling long-term continuous frying operations for banana chips. The system is equipped with a heavy-duty circulation pump and a PLC control system to maintain stable frying temperatures and improve thermal efficiency. Powered by an LPG gas-burning system, the fryer supports temperatures up to 210°C, with adjustable frying times ranging from 4 to 10 minutes. Constructed with SUS #304 stainless steel (except motor and pump), the machine complies with food processing standards. It also features double stainless steel conveyor nets and four paddles controlled by two speed controllers, ensuring uniform product movement and even heat distribution throughout the frying process—ideal for industrial-scale banana chips manufacturing.

4. Vibratory De-oiling Conveyor

The vibratory de-oiling conveyor designed to remove excess surface oil after frying and enhance product crispness while lowering overall oil content. Featuring a stainless steel mesh conveyor, the system allows oil to drain efficiently during conveying. An adjustable vibration frequency enables fine-tuning according to product thickness and production capacity, ensuring stable de-oiling performance without damaging the banana chips. Driven by a 1 HP motor, the robust structure delivers reliable vibration and continuous operation, making it an essential downstream component in industrial banana chips processing lines to improve product quality consistency and reduce seasoning load.

5. Q.C. Conveyor

The Q.C. Conveyor is a critical quality control unit in the downstream section of a banana chips production line, designed for product cooling and final inspection after frying. Featuring a stainless steel mesh conveyor, it allows banana chips to cool naturally during conveying while maintaining product dryness. The system is equipped with two bypass inspection channels separated by guard rails along the main conveyor, enabling operators to efficiently remove defective products and significantly improve quality checking efficiency. Driven by a 1/4 HP motor, the conveyor delivers stable performance and is well suited for continuous banana chips processing lines, helping manufacturers maintain high productivity while ensuring consistent product quality and food safety.

6. Flavor Sprinkler

The flavor sprinkler designed to evenly apply powdered seasonings onto the surface of banana chips to ensure consistent flavor distribution and stable adhesion. The system utilizes a Teflon screw rod for dry powder feeding, effectively preventing powder bridging or clogging and ensuring smooth, accurate seasoning delivery. Both sprinkling speed and quantity are adjustable to match different recipes and production capacities, enhancing seasoning flexibility while reducing material waste. Constructed with stainless steel, the machine meets food processing hygiene standards and operates reliably with a low-power motor, making it ideal for continuous banana chips processing lines focused on quality and consistency.

7. Seasoning Drum

The seasoning drum designed to ensure uniform coating and consistent flavor quality. This system is used to evenly apply powdered or liquid seasonings onto banana chips. The drum body is constructed using a multi-folded forming method instead of welding, minimizing hygienic blind spots and improving cleaning efficiency in compliance with food processing standards. With a drum diameter of 776 mm and driven by a 1/2 HP motor, the drum provides stable rotation. Both rotation speed and tilting angle are adjustable to precisely control coating time and seasoning coverage, while clockwise (C.W.) and counterclockwise (C.C.W.) rotation options offer greater processing flexibility. Built entirely with stainless steel, the seasoning drum is well suited for continuous banana chips processing lines, enhancing product consistency and overall production efficiency.

8. Discharge Conveyor

The discharge conveyor designed to smoothly transfer seasoned banana chips to packaging equipment or downstream processes without disrupting line operation. With a conveyor width of 300 mm, the system supports stable product discharge and accommodates various production capacities. The adjustable speed feature allows precise synchronization with packaging machines or overall line speed. Constructed with stainless steel (except motor and bearings), the conveyor offers durability, easy sanitation, and compliance with food processing hygiene standards. Driven by a 1/4 HP motor, it provides reliable performance and serves as an essential component for efficient and well-integrated banana chips processing lines.

Production photos LIVE SHOT

raw material: Peeling→

Green bananas are manually peeled after being sent to the factory.(It's easy to cause lots of damage during the process of mechanical peeling because of the different size of bananas. )

Capacity

- In case of different kinds of products and processing processes, please contact our business department and our staffs will be serving you.

Applications

- Snack foods, banana chips, plantain banana

Actual Production

- Actual production footage of potato chips snacks production line equipment

- Actual production footage of potato chips snacks production line equipment

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machinery manufacturer and a supplier of banana chip production lines. From peeling, washing, slicing, quantitative feeding, frying, degreasing, cooling, and seasoning, we can provide complete banana chip frying production line solutions.

If you have a Banana Chips production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

As the global snack food market continues to expand, snack manufacturers face a critical challenge:...

DetailsBanana Chips Production Line Manufacturer

The banana chips production line can be flexibly configured according to different product...

DetailsPoPo Fish Muruku Production Line Manufacturer

The PoPo Fish Muruku and Indian Murukku Production Line is designed for industrial-scale manufacturing...

Details- Videos

- Finished Product Gallery

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Banana Chips Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Banana Chips Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.