Potato Chips Production Line Manufacturer

Potato Crisps Production Line、ポテトチップス、มันฝรั่งแผ่นทอด、มันฝรั่งทอดแผ่นยัก、มันฝรั่งแท่งทอด

The potato chips frying production line provides a fully automatic and continuous solution for snack food manufacturing. The system integrates washing, slicing, blanching, frying, de-oiling, seasoning, and packaging into one efficient process. Built with high-quality stainless steel, it ensures food safety, durability, and easy maintenance. The industrial potato chips continuous frying machine maintains precise temperature control and oil circulation, producing crispy, golden potato chips with consistent texture and flavor. Ideal for large-scale potato chips factories, this energy-efficient frying line helps reduce labor, improve production efficiency, and deliver high-quality fried snacks.

The automatic potato chips frying line is designed with a continuous workflow to ensure smooth and stable production. Fresh potatoes are first washed and peeled, then sliced into uniform thickness before blanching to remove excess starch. The slices are then conveyed into the continuous fryer, where precise temperature control and efficient oil filtration guarantee even frying results and extended oil life. After frying, the chips are de-oiled, cooled, and automatically transferred to the seasoning drum for flavor coating. The entire system can be customized with energy-saving heating methods, CIP cleaning systems, and integrated conveyors, making it a reliable and hygienic choice for modern potato chips manufacturing plants.

Tsung Hsing Food Machinery is a manufacturer and supplier of potato chip production line equipment with extensive experience in processing agricultural products into potato chips.

Features Of Potato Chips Production Line

1. Having 100 kg/hr, 300 kg/hr, and 500 kg/hr optional capacities according to the requirements.

2. PLC control, easy to operate.

3. Optional dumping device for increased automation.

4. Completely detecting the quality of potato raw materials by the roller type inspection testing.

5. Adjustable conveying speed during the entire process.

6. Using the US Urschel slicing machine, which is fast and having good quality.

7. Adjustable slicing shape and thickness of the potato chips.

8. There is a de-water device before frying, which saves the heat energy consumption of the fryer.

9. Adjustable frying temperature and frying time according to the requirements.

10. Safety devices with alarms and shutdowns when the oil is over temperature, the exhaust gas temperature is too high, and the flow pressure difference is abnormal.

11. Indirect heating to extend the shelf life of oil and other products.

12. Automatically replenishing new oil with the level controller.

13. CIP device for quick cleaning of equipment.

14. The upper cover of the fryer can be lifted and lowered to facilitate equipment cleaning.

15. There are upper and lower limit switches during lifting to increase operational safety.

16. The seasoning drum is integrated, safe and hygienic.

17. Inspection and delivery before packaging to ensure product quality.

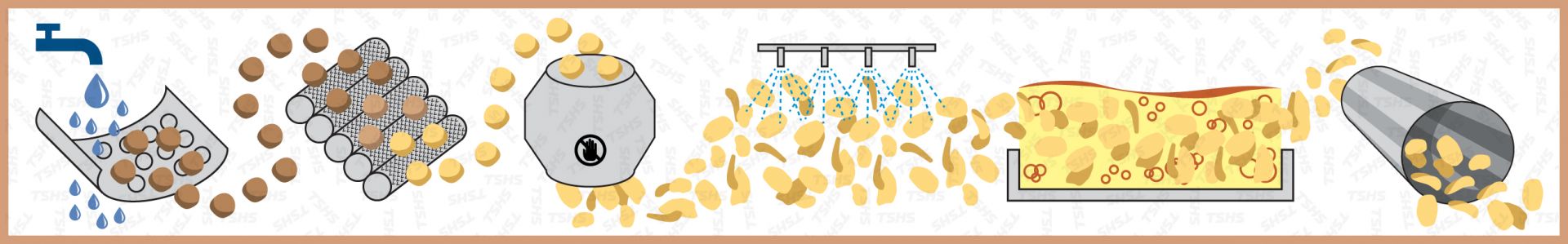

Process

Feeding → Washing → Peeling → Examine → Slice → Starch Washing → Dripping → Continuous Fryer → Dripping → QC Examine → Seasoning → Cooling → Packing

(This is the basic configuration, please contact us for other special processes.)

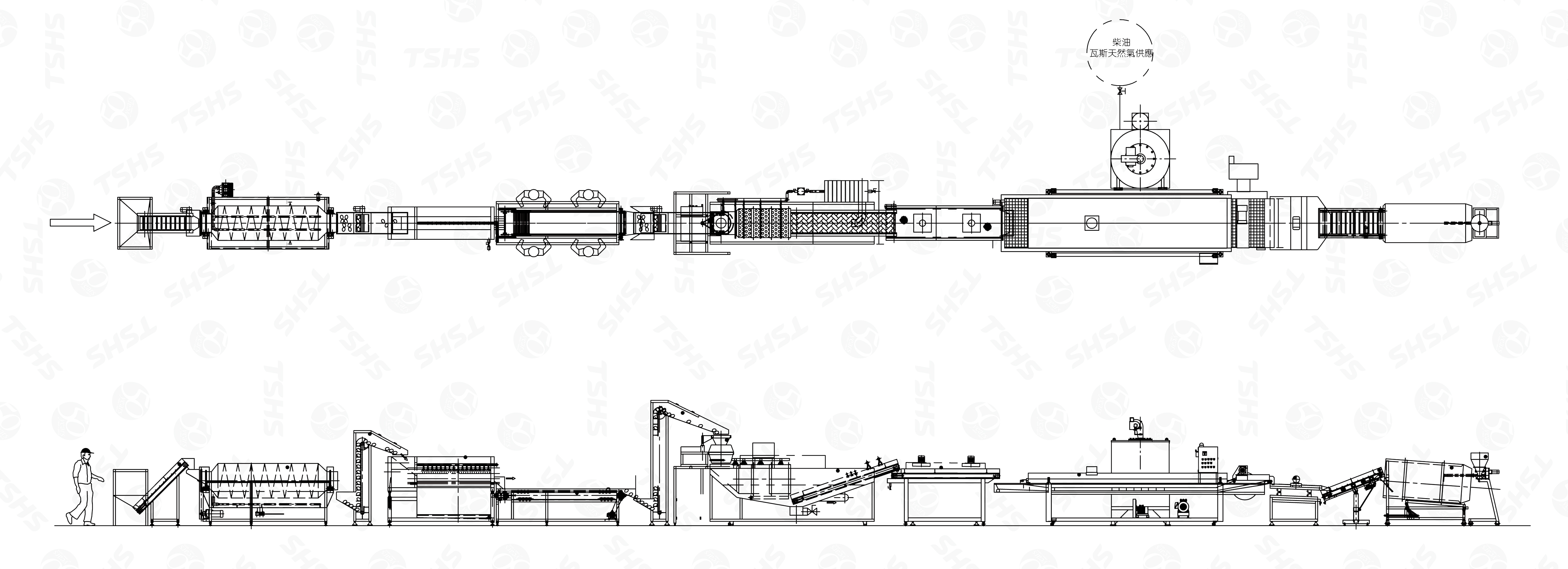

LAYOUT

Equipment Information of Potato Chips Production Line

The potato chips frying production line combines high efficiency, energy savings, and advanced automation to meet global food industry standards. Its modular design allows flexible configuration according to production capacity and product type. All components are made from food-grade stainless steel, ensuring easy maintenance and long-term reliability. With stable temperature control and uniform frying performance, manufacturers can achieve consistent color, crispness, and flavor in every batch. This system is widely applied in potato chips, cassava chips, taro chips, and other fried snack production lines, making it an ideal solution for food factories aiming to expand capacity and enhance product quality. The potato chip production line is a customized equipment. The specifications will be adjusted according to product requirements. Please refer to the official quotation provided by our sales department for the final quote.

1. Feeding Conveyor for Washing M/C

The Feeding Conveyor for Washing M/C is designed to deliver fresh potatoes smoothly and quantitatively into the washing machine, ensuring stable upstream preparation for the potato chips production line. With a compact structure measuring 2000 × 1000 × 1500 mm and powered by a 1/2 HP motor, the conveyor provides reliable and steady material feeding. Its adjustable-speed design keeps the conveyor synchronized with the washing process, enabling fully automatic production and significantly reducing manual handling. Constructed from food-grade stainless steel, it maintains hygiene while improving production efficiency across the potato chips processing workflow.

2. Washing M/C

The Washing M/C performs the first essential stage of the potato chips production line, removing stones, soil, and surface impurities from fresh potatoes using clean, room-temperature water. This drum-type washing machine is engineered with a spiral conveying structure that ensures first-in-first-out (FIFO) movement, providing consistent cleaning and stable material flow. With a size of 3500 × 1500 × 2000 mm and powered by a 2 HP motor, the system offers reliable capacity for continuous production. The adjustable washing time allows operators to fine-tune cleaning intensity based on potato conditions, ensuring higher hygiene standards and smoother downstream processing. Its efficient spiral feeding mechanism improves washing uniformity.

3. Feeding Conveyor for Peeling M/C

The Feeding Conveyor for Peeling M/C transfers washed potatoes smoothly and quantitatively into the peeling machine, ensuring a stable and continuous feeding process within the potato chips production line. Built in a compact size of 2500 × 1000 × 2000 mm and powered by a 1/2 HP motor, the conveyor provides reliable material handling for automated operations. Its adjustable-speed design allows precise synchronization with the peeling machine, helping maintain a consistent workflow while minimizing manual labor.

4. Peeling Machine

The Peeling Machine performs the second key stage of the potato chips production line, enabling continuous and efficient potato peeling. Using a durable carborundum roller, the system gently rubs the potato surface to remove the skin, while a brush wheel further cleans off the remaining residue to achieve a uniform peeling result. With a large structure measuring 3000 × 2000 × 2000 mm and powered by a 3 HP motor, the machine supports stable, high-throughput operation. The peeling time can be adjusted based on product requirements, allowing manufacturers to control peeling intensity and minimize raw material loss. Designed for continuous operation, the machine offers easy operation, low maintenance needs, and reliable performance.

5. Feeding Conveyor for Slicing M/C

The Feeding Conveyor for Slicing M/C ensures that peeled potatoes are delivered quantitatively and steadily into the slicing machine, maintaining a smooth and consistent workflow in the potato chips production line. With a compact footprint of 2500 × 800 × 2500 mm and powered by a 1/2 HP motor, the conveyor provides reliable feeding performance suitable for continuous processing. The system is designed to match the slicing speed, ensuring synchronized operation and reducing the risk of overload or irregular feeding. Additionally, the conveyor is equipped with spacers that enhance material stability during transport, preventing product rolling and improving slice uniformity. This feeding unit strengthens upstream efficiency and contributes to a more stable slicing process.

6. Slicing M/C

The Slicing M/C used in the potato chips production line adopts the world-renowned Urschel slicer from the United States, a leading global manufacturer of professional cutting equipment known for exceptional precision and durability. Operating based on the centrifugal cutting principle, the slicer delivers fast, accurate, and uniform potato slices according to the required thickness. With its compact design measuring 800 × 800 × 1200 mm and powered by a 2 HP motor, the equipment is lightweight, easy to operate, and highly efficient for continuous production. The machine also features a replaceable knife module, allowing manufacturers to produce various product shapes and styles using a single slicer.

7. Starch washing M/C

The Starch Washing M/C is designed to remove excess surface starch from freshly sliced potatoes, preventing dark spots and uneven coloration during frying. This drum-type system features an internal screw-feeding mechanism that gently moves the slices forward while circulating water thoroughly washes away starch. The washing water can be recycled to reduce consumption, and the outlet section uses water-assisted discharge with an additional spray to enhance the final cleanliness of the potato slices. With a structure measuring 4200 × 1600 × 1800 mm and driven by a 2 HP motor, the machine supports continuous washing in high-capacity potato chips production lines. Its stable, controlled flow ensures uniform cleaning and helps improve frying quality and product appearance.

8. Drying Conveyor

The Drying Conveyor removes excess surface moisture from freshly washed potato slices, ensuring better frying performance and preventing oil splashing during the next processing stage. With dimensions of 2000 × 1600 × 1800 mm and powered by a 3 HP motor, the system delivers strong and consistent airflow to achieve effective moisture reduction. The machine uses high-pressure air generated by a roots blower to lift and dry the surface of the potato slices, preparing them for even and uniform frying. The air volume can be adjusted based on product requirements, allowing operators to fine-tune drying intensity for different slice thicknesses and desired moisture levels. This drying step enhances product texture, reduces oil absorption, and improves final chip quality within the potato chips production line.

9. Continuous Oil Fryer

The Continuous Oil Fryer is the core equipment of the potato chips production line, responsible for maintaining stable oil temperature and ensuring consistent frying quality. The system heats the frying oil through a dedicated heating unit and precisely controls the air–fuel ratio to deliver efficient and uniform heat transfer. With a large structure measuring 8500 × 2400 × 2500 mm and driven by a 30 HP motor, the fryer supports continuous high-capacity production.

Equipped with a PLC touch control panel, operators can easily set and monitor frying temperature, frying time, and system status. Multiple built-in safety devices ensure operator protection and stable equipment performance. During frying, the automatic filtration system continuously removes residue, extending the service life of the frying oil and maintaining product color and quality. An integrated automatic cleaning (CIP) function further reduces downtime and cleaning labor.

10. Seasoning System

The Seasoning System of the potato chips production line consists of a powder feeder and a rotating seasoning drum, designed to evenly coat chips with flavoring powder to enhance product taste and consistency. The screw-type dosing device delivers seasoning powder quantitatively into the drum, ensuring accurate feed rates for stable production. As the drum rotates, potato chips are gently tumbled to achieve uniform coating and an appealing appearance. With dimensions of 2500 × 1500 × 1600 mm and powered by a 2 HP motor, the system supports continuous operation and high-capacity output. The tilt angle of the drum can be adjusted to control mixing time, allowing manufacturers to fine-tune flavor intensity and coating uniformity. This flavoring system is suitable for a variety of snack foods and helps produce high-quality potato chips with a consistently good taste.

11. Discharge Conveyor

The Discharge Conveyor is the final transfer unit in the potato chips production line, responsible for delivering the seasoned chips quantitatively and steadily to the next stage of processing. With dimensions of 2000 × 800 × 1200 mm and powered by a 1/2 HP motor, the conveyor ensures smooth discharge flow without damaging the delicate chips. Designed for flexible integration, the discharge conveyor can be automatically connected to various packaging systems, enabling seamless transitions from seasoning to packing.

PERIPHERALS / ACCESSORIES

1. Pouring M/C

The Pouring M/C is designed to automate the initial feeding stage of the potato chips production line by lifting and pouring full containers of raw potatoes directly into the hopper. This hydraulically driven system provides stable and controlled pouring, capable of handling approximately one ton of potatoes per cycle, significantly reducing manual labor and improving workplace safety. With a structure measuring 1500 × 1500 × 2000 mm and powered by a 1/2 HP motor, the machine delivers reliable performance for high-volume processing. The automatic pouring mechanism ensures consistent feeding, minimizes product damage, and enhances the overall efficiency of upstream material handling.

2. Continuous Fine Filter

The Continuous Fine Filter plays a crucial role in maintaining frying oil quality within the potato chips production line. Designed for continuous in-line filtration, the system removes fine particles and residues generated during frying to ensure the oil remains clean and stable throughout production. With a compact structure of 1750 × 1410 × 1760 mm, a 70 mm conveyor width, and powered by a 1/4 HP motor, the machine operates efficiently without interrupting the frying process. The filtration performance reaches up to 80 mesh, effectively capturing fine impurities and significantly extending the service life of the frying oil. This continuous filtering mechanism enhances product color consistency, reduces oil consumption, and ensures stable, high-quality fried potato chips.

3. De-oil conveyor

The De-oil Conveyor is designed to effectively reduce the surface oil content of freshly fried potato chips, helping improve product texture and extend shelf life. With a large structure measuring 5000 × 1800 × 2500 mm and powered by a 5 HP motor, the system supports continuous high-throughput production. Using the principle of centrifugal force, excess oil is removed from the chips as they are conveyed forward, ensuring a stable and efficient de-oiling process. When connected with the upstream feeding conveyor, the system operates in a fully continuous mode, reducing manual handling while maintaining consistent product quality. This de-oiling mechanism enhances crispness, lowers oil absorption, and prepares the chips for seasoning and packaging stages.

4. Water recovery system

The Water Recovery System is designed to reduce water consumption throughout the potato chips production line by recycling and reusing process water from washing and starch-removal stages. Depending on production capacity and factory requirements, the system can be configured to achieve significant water-saving performance while maintaining hygiene and processing efficiency. Through sediment separation, preliminary filtration, and controlled water circulation, the recovered water can be reused for non-critical rinsing or pre-washing steps, helping manufacturers lower operating costs and meet environmental sustainability standards. This system plays an important role in optimizing resource usage and supporting eco-friendly potato chips processing.

5. Color Sorter

The Color Sorter is designed to automatically and continuously remove defective potato chips during production, ensuring consistent product quality before entering the final packaging stage. With dimensions of 3000 × 1800 × 2000 mm, the machine uses advanced optical detection technology to identify chips with discoloration, burning, or imperfections. Once color differences are detected, targeted air-jet pressure instantly removes the defective pieces from the product flow, enabling accurate and efficient online sorting. This fully automated system enhances quality control, reduces manual inspection needs, and ensures that only uniform, high-quality potato chips proceed to the next stage of processing.

6. Packaging M/C

The Packaging M/C is the final stage of the potato chips production line, responsible for sealing finished products efficiently and ensuring long-term freshness. Designed for high-speed and continuous operation, the system can be adjusted according to production capacity and packaging requirements, offering flexibility for different bag sizes, filling weights, and sealing specifications. The packaging machine can be seamlessly integrated with upstream conveyors, weighing systems, and metal detectors to form a fully automated packing process. Its stable sealing performance reduces product exposure to air and moisture, extending shelf life while maintaining product quality and appearance.

Capacity

- 100kg/hr (PC100)

- 300kg/hr (PC300)

- 500kg/hr (PC500)

Applications

- Potato chips, sweet potato chips, taro chips, cassava chips, potato chips

| Flaky | Wavy | Strip Shape |

|

|

|

| Potato Chips | Sweet Potato Chips | Taro Chips | Cassava Chips |

|

|

|

|

-

Actual production footage of potato chip production line equipment

-

Actual production footage of potato chip production line equipment

-

Actual production footage of potato chip production line equipment

-

Actual production footage of potato chip production line equipment

-

Actual production footage of potato chip production line equipment

-

Actual production footage of potato chip production line equipment

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machinery manufacturer and supplier of potato chip production lines. From cleaning, peeling, slicing, washing, frying, and seasoning, we can provide complete potato chip frying production line solutions.

- Related Products

-

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details - Videos

- Finished Product Gallery

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Potato Chips Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Potato Chips Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.