Fish Shred Production Line Manufacturer

Thai BENTO fish fillets, Chinese Fragrant fillet or Surimi Fish Snack、Malaysian Gindaco

The fish shred production line uses fish paste as its primary raw material and processes it through continuous mixing, sheet forming, pre-baking, drying, seasoning soaking, air drying, and roasting stages to gradually build a stable texture and layered structure. A multi-stage cutting-type shredder, consisting of length-cutting and fine strip-cutting modules, is applied at the final step to transform roasted fish-paste sheets into uniform shredded strands. This fully automated fish shred processing line enhances production efficiency, reduces labor dependency, and ensures consistent color, texture, and product dimensions. It is ideal for manufacturing fish shreds, seafood-flavored strip snacks, and various imitation seafood products.

The Pollack Fish Snack can be said to be a classical Taiwanese snack, and many people have fond childhood memories of it. It is said that the pollack fish snack was invented by the Japanese and later passed to Taiwan. It was considered a high class import food that gradually became an important product in the surimi processing industry in Taiwan. Related applications are widely used in various Asian countries.

Features Of Fish Shred Production Line

1. The product is made from surimi as the main raw material, and different processing methods and processes are derived. Different product applications are available. Such as Thailand's well-known BENTO fish fillets, Japanese natori surimi fish snack, Chinese fragrant fillet or surimi fish snack, Malaysian gindaco.

2. TSHS provides automatic production of the Fish Shred Production Line with stable quality control. And the design emphasizes: the equipment is easy to operate and made of stainless steel, which compliances food hygiene and safety. Manpower economizing, and increasing efficiency.

3. Stable drying & roasting performance: Multi-zone temperature control ensures uniform moisture removal and consistent color development while preventing over-drying or scorching.

4. High-precision cutting system: A multi-stage cutting-type shredder enables adjustable strip length and width, providing flexibility for various shred styles.

5. Superior product consistency: From sheet formation to final shredding, the line ensures uniform thickness, texture, and flavor across every production batch.

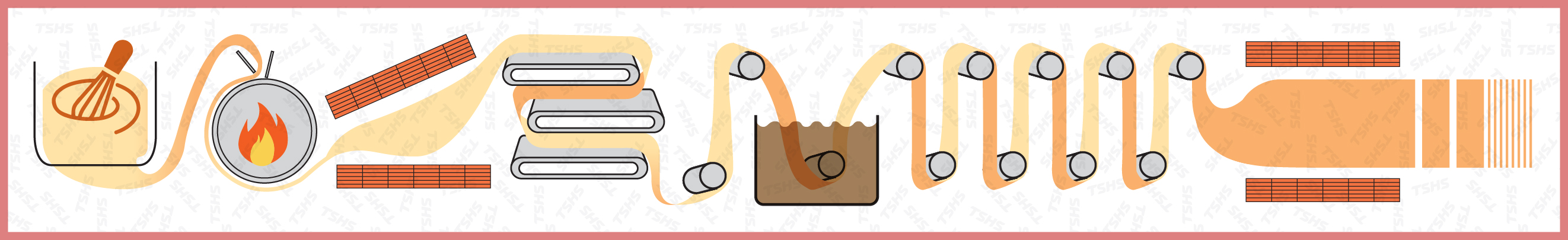

Process

Ten operation works: Surimi Mixing→ Ejecting→ Pre-baking→ Drying→ Dipping→ Baking→ Cutting→ Shredding. (This is the basic configuration, please contact us for other special processes.)

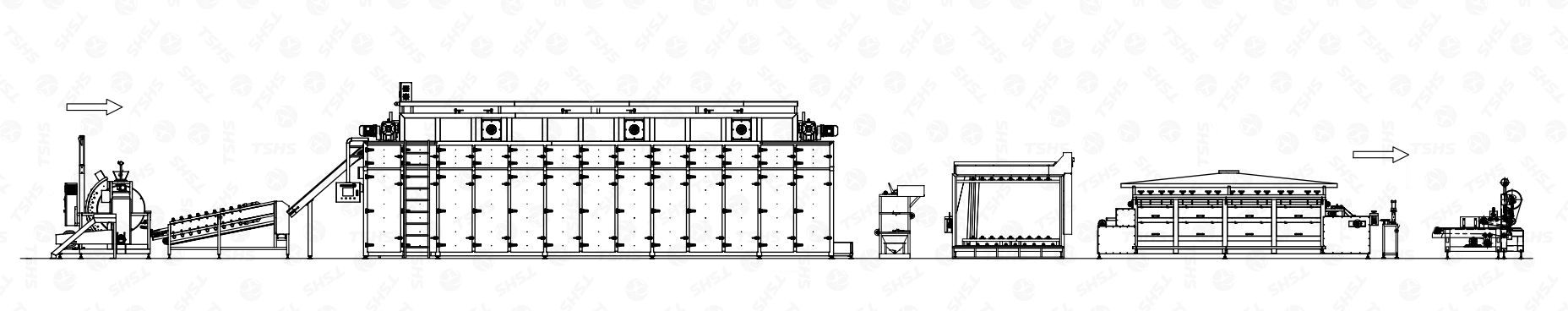

LAYOUT

Equipment Information of Shredded Fish Snack Production Line

The raw materials of fish shred are mainly surimi, wheat flour, sugar, salt, etc., and are processed into high speed crushing strainer, beating, seasoning, stirring and other processes to make surimi raw materials. The surimi is then extruded into a sheet shape through a ejector, dried, dipped, air-dried, and then cut into a filament by a wire cutter after being cut and cooled by a high-temperature baking to complete the production. The fish shred production line is a customized equipment. The specifications will be adjusted according to product requirements. Please refer to the official quotation provided by our sales department for the final quote.

1. Surimi Raw Material Mixing

The Surimi Raw Material Mixing system serves as the first critical step of the fish shred production line, where surimi paste, surimi flour, and seasonings are added into a high-speed crushing strainer for cutting and mixing. This process refines the paste into a smoother, more uniform texture, enhancing product flavor while preventing clogging during downstream production. The High Speed Crushing Strainer features a 304 stainless-steel pot body, an aluminum alloy lid and discharge port, and SUS420 stainless-steel cutting blades to ensure durability and food safety. With dimensions of Length 2910 × Width 2010 × Height 1570 mm and a 50 HP power requirement, the system efficiently handles large-volume homogenization within a short processing time. Consistent mixing quality ensures stable sheet forming, drying, and roasting performance, making this unit a vital component of the entire fish shred processing equipment setup.

2. Forming Machine

The Forming Machine is responsible for delivering the mixed surimi paste to the molding system and shaping it into uniform sheets, making it an essential component of the fish shred production line. The stirred surimi is pumped into the storage drum by a screw pump, where it undergoes slight maturation through controlled heating. The paste is then evenly extruded through a roller to form consistent fish sheets, which are scraped off by a built-in scraper and transferred into the pre-baking oven. The machine utilizes an infrared heating system to achieve efficient and uniform thermal processing. Its ejector roller is constructed from 304 stainless steel and internally cooled with circulating water to maintain stable forming conditions. With a wheel width of 1050 mm, the system can extrude two fish sheets simultaneously, significantly boosting production efficiency. The unit measures 4015 × 1675 × 2120 mm and requires 1 HP × 1 + 1/4 HP × 1 power, ensuring continuous, reliable sheet forming for downstream drying and roasting processes.

3. Pre Baking M/C

The Pre-Baking Machine in the fish shred production line utilizes gas infrared fire tubes to rapidly remove surface moisture from the formed surimi sheets. This quick drying action creates a thin, dry layer on the surface, preventing the sheets from sticking to the mesh belt during the next processing stage. The unit is equipped with a stainless-steel conveyor belt that offers stable, deformation-resistant conveying under high temperatures. Its infrared heating system delivers fast response and uniform heat distribution, improving pre-baking quality and overall processing efficiency. With dimensions of 2950 × 1100 × 1300 mm and a power requirement of only 1/4 HP, the machine is well-suited for continuous industrial operation, ensuring stable sheet quality before entering the drying and roasting stages.

4. Dryer

The Dryer in the fish shred production line is fully constructed from stainless steel to meet food hygiene regulations, ensuring durability and easy sanitation. Its heating system uses a gas direct-fire burner, providing high heating efficiency with clean and non-polluting combustion. The hot air circulation system incorporates stainless-steel turbo-type blowers arranged in a crosswise configuration, allowing uniform airflow without dead corners. This ensures that surimi sheets receive even heating throughout the drying process, resulting in consistent moisture control and optimal product quality.

The 11-layer conveyor-type auto dryer (Model WS-206) features an outer dimension of 12295 × 2435 × 3500 mm and an inner drying chamber dimension of 10000 × 1342 × 2590 mm. The conveyor is driven by a 3 HP TECO motor with reducer, while hot air circulation is powered by a 2 HP TECO blower. Engineered for long-duration continuous production, this dryer provides reliable performance and is a crucial component for achieving stable output and high-quality results in the fish shred production line.

5. Dipping M/C

The Dipping Machine in the fish shred production line is fully constructed from stainless steel to meet food hygiene regulations and ensure product safety throughout the process. As the surimi sheets pass through the dipping section, a specially designed vertical wrap system allows the sauce to be evenly coated onto the surface. A food-grade steel scraper removes excess seasoning to achieve a consistent coating thickness and the best flavor performance. This unit is driven by an adjustable motor with deceleration control, allowing fine tuning of dipping speed based on production requirements. The machine measures 870 × 1420 × 1622 mm and operates with a 1/2 HP motor, making it suitable for continuous high-volume seasoning processes and ensuring uniform taste and appearance in every batch of fish shred products.

6. Hanging Air Dryer

The Hanging Air Dryer in the fish shred production line is designed to naturally air-dry the coated surimi sheets, allowing the surface seasoning to slowly penetrate into the inner layers of the product. This gentle drying method enhances flavor depth without causing surface hardening or moisture imbalance. As the dipped sheets are suspended in the airflow, the seasoning gradually diffuses throughout the surimi, improving texture and overall taste uniformity. The unit is driven by an adjustable motor with deceleration control, enabling precise adjustment of drying duration and conveyor speed based on production requirements. With dimensions of 2730 × 1950 × 2055 mm, the Hanging Air Dryer supports continuous air-drying operations and plays an essential role in achieving consistent flavor absorption and high-quality results in the fish shred production process.

7. Infra-Red Conveyor Oven

The gas infrared conveyor oven in the fish shred production line uses infrared radiation to heat and bake the surimi sheets. The radiant heat penetrates directly into the product, allowing rapid ripening and controlled foaming that enhance texture and overall taste. This efficient heating method ensures that the fish sheets develop a light, expanded structure with improved mouthfeel. The conveyor system, equipped with an adjustable motor and deceleration control, enables precise setting of baking time to achieve consistent results across every batch. With dimensions of 5800 × 1000 × 860 mm and a power requirement of 1 HP, the oven is designed for continuous production and plays a vital role in defining the final texture and flavor quality of fish shred products.

LIVE SHOT

| raw material | Production process |

|

|

| Finished Product | |

|

|

Applications

- Fish Snacks, Dried Fish Fillet, Black Sesame Sandwich Wire

-

Actual production footage of fish shred snacks production line equipment

-

Actual production footage of fish shred snacks production line equipment

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machinery manufacturer and supplier of shredded fish snacks production lines. From surimi mixing, ejecting, pre-baking, drying, dipping, baking, cutting, shredding, we can provide complete shredded squid or fish snack seafood production line solutions.

If you have a Shredded Fish Snacks production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

-

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details - Videos

- Finished Product Gallery

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Fish Shred Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Fish Shred Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.