Green Pea Production Line Manufacturer

Cina、فاصولياء خضراء、Pea、Green Pea、Garlic Green Pea、Frying Green Pea、Pick Pea

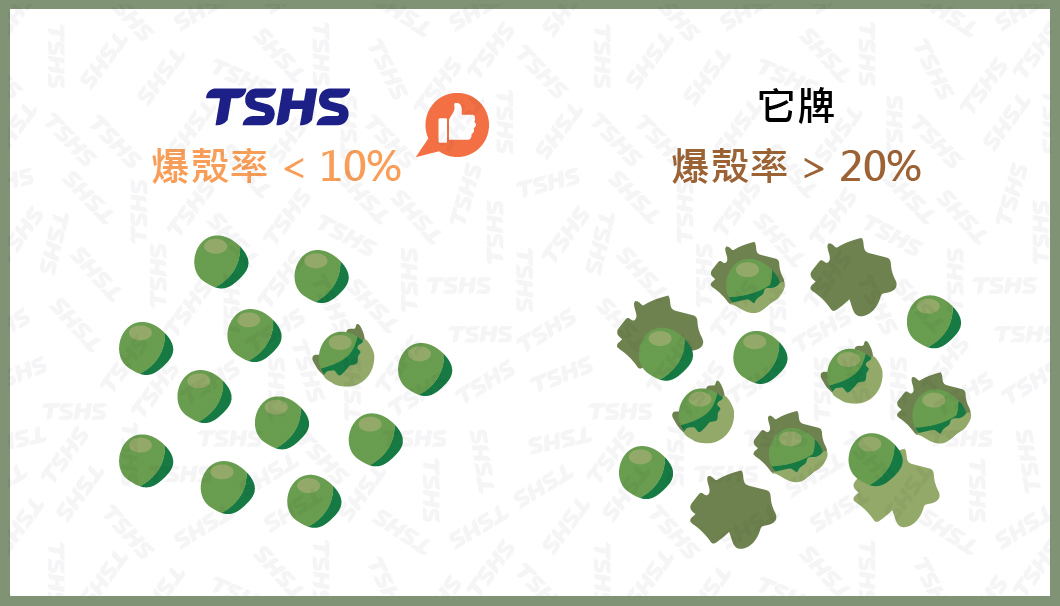

The most worrying customers are the quality of the products during the production of Frying Green Pea. In the production process, the increase in the defect rate of the product is often caused by the improper control of the frying temperature, which causes the customer's product to have burst of the pea or the different appearance. The continuous frying machine of TsungHsing Food Machinery uses a temperature-stable mechanism to help customers to prevent burst of the green pea of the frying process and enhance the product quality.

TSHS Green Pea Frying Production Line is specifically designed to produce crispy and delicious fried green pea snacks. As a complete green pea processing equipment solution, it integrates raw material handling, pre-cooking, coating, frying, de-oiling, seasoning, and cooling into a fully automated system to ensure stable and efficient continuous production. The integrated green pea frying machine features precise high-temperature control and advanced oil management, guaranteeing that each fried green pea is golden in appearance and crunchy in texture—highly favored by the snack market.

With the addition of a seasoning system, the line can produce a variety of flavors such as original, wasabi, or spicy green peas. TSHS offers a one-stop green pea processing equipment solution ideal for medium to large-scale food processing factories. This system enhances automation, reduces labor demands, and ensures consistent product quality—helping manufacturers expand capacity and improve overall production efficiency.

Features Of Green Pea Production Line

1. High and diverse yield.

2. Stable quality to prevent burst of the pea.

3. High value added product and it’s easy to produce.

4. Economize manpower by automatic production line.

5. Safe and hygienic from integrated production.

6. Labor and energy saving.

Process

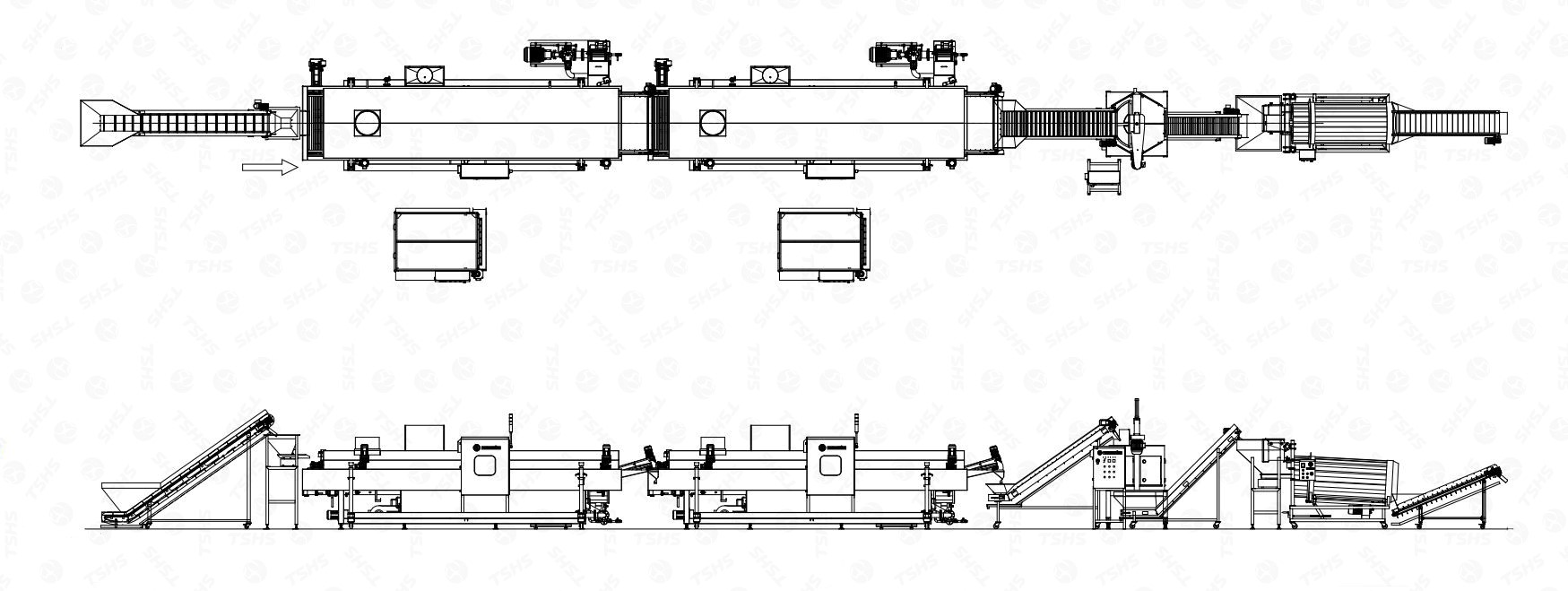

Soaking → Dehydration → Screening Machine → Quantitative Feeding → Fryer → De-oiling System → Sprinkling Seasoning system → Packing (This is the basic configuration, please contact us for other special processes.)

LAYOUT

Equipment Information of Green Pea Production Line

This section provides a comprehensive introduction to the key machinery and systems that make up a complete green pea processing line. From soaking and dehydration to frying, de-oiling, cooling, and seasoning, each stage is supported by modular equipment designed for high performance, hygiene, and continuous operation. Whether you are looking to build a fried green pea production line or upgrade specific components, this detailed overview will help you understand the functions, advantages, and integration potential of each unit within your snack food manufacturing process.

1. Soaking

Depending on the variety, green peas must be soaked in clean water with food-grade coloring for 8–12 hours before processing. During this stage, peas with undesirable appearance or poor quality are removed to ensure consistent raw material quality. This critical step lays the foundation for a premium snack texture. Once soaking is complete, the green peas are transferred into the fried green pea production line for further processing.

2. Dehydration

To prevent oil degradation and product bursting during frying, excess surface water must be removed. The green pea processing equipment includes a high-efficiency dehydration system that allows operators to adjust speed and capacity without damaging the product. This guarantees optimal moisture levels for consistent frying results.

3. In-feed Conveyor

The in-feed conveyor links upstream processing to frying. It ensures smooth, controlled transfer of green peas into the fryer, maintaining a steady pace throughout the line and supporting the efficiency of the automatic snack production line.

4. Screening Tumbler Machine

Equipped with an automated screening system, the green pea frying line classifies green peas by size using customizable mesh sieves. This process helps standardize product appearance and reduce size variation, ensuring a uniform final product while maintaining high quality.

5. Quantitative Feeding

A vibration feeder delivers peas at a consistent rate into the fryer, stabilizing oil temperature and ensuring even cooking. Adjustable vibration frequency allows flexible control based on production capacity. This system prevents undercooking or overcooking caused by sudden oil temperature fluctuations, ensuring ideal frying performance.

6. Fryer

The frying equipment provided by the Frying Green Pea Production Line of Tsung Hsing Food Machinery has the added value of energy saving, space saving, oil saving, and high heat exchange rate and recovery rate. The fully automatic control system saves the time for personnel to operate, and also keeps the oil temperature at a certain temperature during the frying process, and ensures the first-in-first-out of the product through the continuous mesh belt to prevent material accumulation. Because of the frying temperature required for fried Green Pea can’t be too high, to prevent the burst of the pea. In addition to convenient subsequent seasoning and packaging process, it also maintains the quality of Green Pea in the production process and the taste after production.

7.De-oiling

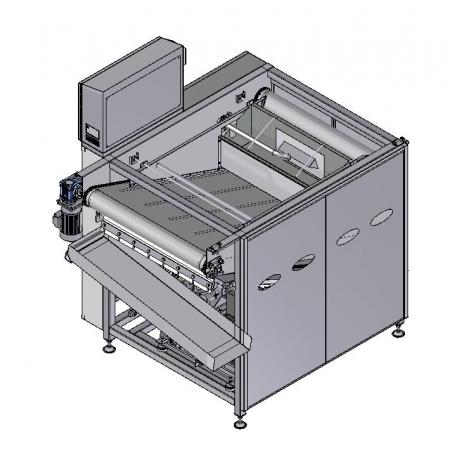

After frying, peas enter the centrifugal de-oiling machine—a hexagonal design that spins off excess surface oil while maintaining product integrity. The system is low-maintenance, easy to clean, and supports continuous operation, helping manufacturers reduce labor costs and increase throughput. It's a crucial part of modern green pea processing equipment focused on snack health and oil efficiency.

8. Cooling Conveyor

After de-oiling, The green peas enter the cooling conveyor, which rapidly reduces the surface temperature to stabilize the product before seasoning and packaging. Due to the high density of green peas, heat tends to be retained within the core. Therefore, a forced air cooling system is applied to ensure even and efficient cooling throughout the product. This method helps preserve the crispy texture, prevent moisture accumulation, and extend shelf life.

9. Sprinkling and Seasoning

The seasoning equipment allows precise control over the timing and quantity of seasoning applied. With a seamless drum design, it is easy to clean and maintain, supporting hygienic production in compliance with food safety standards. This machine ensures even distribution of flavor, reduces waste, and enhances product consistency across large batches. The rotary seasoning drum rotates green peas gently while applying powdered or liquid seasoning. With adjustable rotation speed and spray intensity, it enables quick flavor changeovers and ensures uniform coverage. Whether you're producing wasabi, spicy, or classic salted green peas, this snack food seasoning machine is built to deliver both flexibility and consistency.

PERIPHERALS / ACCESSORIES

1. Fine Filter

The fine oil filter is an auxiliary device used in frying production lines, specifically designed for the continuous filtration of residue and fine particles from frying oil. It operates seamlessly during production, helping to maintain oil purity and extend oil life. The equipment dimensions are 1750 mm (L) × 1410 mm (W) × 1760 mm (H), and it features a 970 mm wide conveyor belt. With a power requirement of only 1/4 HP, it is both energy-efficient and highly effective. This system adopts an in-line continuous filtration design, allowing real-time removal of impurities during frying. By preventing the accumulation of carbonized particles, it reduces oil degradation and ensures stable oil quality. With a filtration precision of up to 80 mesh, it guarantees clean oil, which in turn contributes to consistent product color, texture, and overall frying quality—ultimately enhancing production efficiency and final product value.

2. Roaster

The roasting machine is a versatile heating device used in the processing of green peas and other food products. It is suitable for pan-roasting, dry-frying, or drying applications and can be flexibly integrated into various production lines. The equipment measures 3200 mm (L) × 2650 mm (W) × 2320 mm (H), with an effective heating area of 2400 mm (L) × 2100 mm (W) × 160 mm (H). Powered by a 5 HP motor, it provides a stable and robust heat source to support continuous production. The machine's standout feature is its individually controlled burners, allowing operators to adjust the heat intensity of each burner according to specific product requirements. This enables precise temperature zoning, enhancing process flexibility and ensuring consistent product quality. Whether used for roasting legumes, pan-frying mixed ingredients, preheating, or flavor enhancement, this machine delivers efficient and uniform heat treatment across a wide range of food applications.

Capacity

- 150 kg/hr (TSHS-GP-150)

- 300 kg/hr (TSHS-GP-300)

- 500 kg/hr (TSHS-GP-500)

- 700 kg/hr (TSHS-GP-700)

Applications

- Frying Pea Production Line

- Frying Nut Production Line

- Frying Broad Bean Production Line

- United State Fried Green Pea Snacks

- Middle East Fried Green Pea Snacks

- Indonesia Fried Green Pea Snacks

- Thailand Fried Green Pea Snacks

- Australia Fried Green Pea Snacks

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machine manufacturer and supplier of Green Pea Production Line. From frying, drying and seasoning. We can provide complete Green Pea Frying production line solutions.

If you have a Green Pea production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details- Videos

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Green Pea Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Green Pea Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.