Noodle Snacks Production Line Manufacturer

Fried Noodle Snack Production Line, Snacks Noodle, ขนมขาไก่, 麺スナック, نودل سناك, Nuts Roaster

The noodle snack frying production line features fully automated continuous fryers and advanced noodle snack processing equipment, suitable for manufacturing various types of instant fried noodle products. This frying noodle snack manufacturing line offers easy operation and stable performance, utilizing automation to reduce oil consumption and production costs, helping food manufacturers quickly enhance product quality and market competitiveness. TSHS provides comprehensive solutions tailored to your production requirements.

Tsung Hsing Food Machinery is a noodle snacks production line machine manufacturer and snack food machinery supplier. Noodle snacks (also known as snack noodles、ขนมขาไก่、麺スナック、نودل سناك) are the bulk of the snack food market in Asia. Using the simple raw material - flour, which is easy to obtain around the world, mixed with water and other raw material to stir into dough, then stretched into crust, cut with a knife, and after frying and seasoning, it can produce the snack foods which are suitable for all ages and delicious. For snack food, the most common are fried noodle snack and crispy noodles. Among the long-term products in the Taiwan market, the most famous one are the “everyone says GOOD GOOD EAT” series products of Wei Lih food company. In Japan is the Baby Star Crispy Noodle Snack of OYATSU company (ベビースターラーメン). In Malaysia is the New Star company's brand Snek ku is also quite popular in the Thai market, the fried noodle snacks were made into the shape of chicken legs, let the word chicken leg (ขนมขาไก่) become the representative of Thai fried noodle snacks.

Tsung Hsing Food Machinery provides noodle snack frying solution and turnkey noodle snack equipment. Our team has ability design the automated frying system and noodle snack production line that meet safety, hygiene, and high quality requirements, making the production process more easier and high-efficiency noodle frying.

Features Of Noodle Snack Production Line

1. Raw materials are easy to obtain.

2. Popular taste.

3. Stable quality.

4. Large output (300~500kg).

5. Easy to produce with high additional value.

6. Automate production lines and save manpower.

7. Consistent operation, safe and hygienic.

8. Changeable shape by replaceable blade.

9. Easy to clean and maintain.

Process

Raw Material Mixing → Rolling → Stamping → Strip/ Piece Cutting → Fryer → Seasoning → Cooling. (In case of different products, please contact our business department and our consultant will be serving you.)

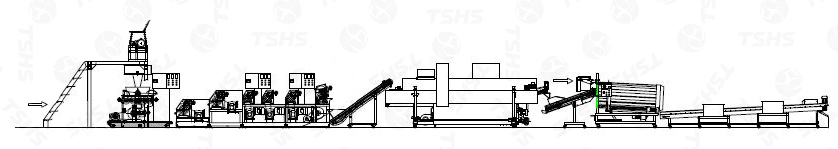

Machine Layout

Equipment Information of Noodle Snack Production Line

After the flour, water and other formulas are stirred into dough, they are cut into the preliminary shape of the fried noodle snack by compounding, rolling, stamping and strip/ piece cutting, and then fried the product to a crispy taste, and seasoned, and the product is cooled before proceeding. Packaging to maintain product yield, stability and quality.

The machine specifications will be adjusted according to product requirements. Please refer to the official quotation provided by our sales department for the final quote.

1. Stainless Double-axles Stirring Machine

The stainless steel double-shaft mixer has a capacity of 125 kg per batch and is powered by a robust 15 HP TECO motor combined with a reliable Sumitomo cycloidal gear reducer. It features an adjustable mixing timer with automatic stop functionality, ensuring consistent product quality. Safety is prioritized with an emergency stop button and interlock cover switch, along with a pneumatic discharge valve for convenient and safe unloading, making it an ideal choice for noodle snack production lines.

2. Rolling Machine

The machine includes an integrated feeder and conveyor for streamlined production. It offers variable frequency drive (VFD) for manual roller speed adjustments, as well as photoelectric sensors and automatic frequency speed controls for precise and automatic roller speed regulation, optimizing efficiency in noodle snack production lines.

3. Cutting Machine (Special Specification)

The special specification cutting machine features a powerful 5.5 HP TECO motor paired with a planetary speed reducer, providing reliable and consistent performance. Equipped with frequency speed control, it allows operators precise adjustments to cutting speed, ensuring accurate sizing for noodle snack production. Additionally, the machine includes an adjustable thickness setting, offering flexibility and uniformity in production to meet diverse snack manufacturing needs.

4. Three-dimensional Steamer

The noodle steaming machine is designed to pre-cook noodle through high-temperature steam, ensuring proper gelatinization and texture before frying. It provides stable steam distribution, precise temperature control (Maximum temperature 110°C), and adjustable steaming time, allowing consistent cooking results. The noodle steaming machine offers user-friendly control over steam flow rate, temperature, and processing time, ensuring consistent and precise steaming results. It is equipped with an electronic or digital temperature controller, which provides a modern appearance and convenient operation. The conveyor chain adopts a side-wheel design that effectively prevents mechanical failures, enhancing reliability and reducing maintenance in continuous noodle snack production.

5. Dipping & Three-layers Stretching Machine

The dipping and three-layers Stretching Machine, measures 10,000 mm (L) × 1,118 mm (W) × 2,700 mm (H) and weighs approximately 2,000 kg. Built with SUS304 stainless steel for durable and hygienic operation. Key functions include the uniform absorption of seasoning into noodle dough before the organizational pore, resulting in seasoning assimilate easily and better flavor penetration. A high-pressure fan system efficiently removes excess sauce, seasoning, and residue, minimizing oil contamination and extending fryer oil life. This equipment is essential for enhancing flavor consistency and frying performance in noodle snack production lines.

6. Cutting Conveyor

The cutting conveyor measures 2,000 mm (L) × 1,304 mm (W) × 1,655 mm (H) and weighs approximately 300 kg. Constructed entirely from SUS304 stainless steel. The system ensures stable and accurate cutting performance. Designed for durability, hygiene, and efficiency, this cutting conveyor is a key component in noodle snack production lines, enabling clean and consistent noodle portioning before frying.

7. Continuous Deep oil fryer

The continuous deep oil fryer is a high-performance frying system designed for noodle snack production lines, featuring an adjustable frying temperature and time for precise cooking control. Internal heat exchanger for efficient heating and oil stability. The integrated screw rod lifting system and CIP (Clean-In-Place) system simplify maintenance and hygiene management, making it ideal for continuous, high-volume snack frying operations.

8. Seasoning Drum

The seasoning drum is designed for efficient, continuous seasoning in noodle snack production lines. It features a multi-angle folded structure that ensures even seasoning coverage and maintains high hygiene standards. The rotation speed and drum angle are fully adjustable, allowing precise control of coating time. Powered by a 1/2 HP drive motor, the drum gently tumbles products using its unique internal structure to achieve uniform seasoning without damaging the product. Ideal for high-capacity, automated snack processing operations.

The in-feed conveyor to the 5-layer continuous drying machine is designed to ensure accurate and consistent delivery of raw materials for the drying process. It features a wide food-grade Teflon conveyor belt with flights, enabling precise quantity control during feeding. The multi-function conveyor ensures smooth, hygienic, and efficient material transfer. Ideal for maintaining a stable conveying before drying operation in noodle snack production lines.

The in-feed conveyor to the 5-layer continuous drying machine is designed to ensure accurate and consistent delivery of raw materials for the drying process. It features a wide food-grade Teflon conveyor belt with flights, enabling precise quantity control during feeding. The multi-function conveyor ensures smooth, hygienic, and efficient material transfer. Ideal for maintaining a stable conveying before drying operation in noodle snack production lines.

The in-feed conveyor to the 5-layer continuous drying machine is designed to ensure accurate and consistent delivery of raw materials for the drying process. It features a wide food-grade Teflon conveyor belt with flights, enabling precise quantity control during feeding. The multi-function conveyor ensures smooth, hygienic, and efficient material transfer. Ideal for maintaining a stable conveying before drying operation in noodle snack production lines.

The in-feed conveyor to the 5-layer continuous drying machine is designed to ensure accurate and consistent delivery of raw materials for the drying process. It features a wide food-grade Teflon conveyor belt with flights, enabling precise quantity control during feeding. The multi-function conveyor ensures smooth, hygienic, and efficient material transfer. Ideal for maintaining a stable conveying before drying operation in noodle snack production lines.

10. 5-Layer Continuous Drying Machine

The 5-layer continuous drying machine is designed for efficient and uniform dehydration of noodle snacks. Featuring a fully stainless steel structure with thermal insulation, this dryer ensures consistent drying results while maintaining hygiene and durability. With multi-layer independent belt control, precise temperature regulation, and a reliable hot air circulation system, it supports high-capacity, energy-efficient operation. The built-in cleaning system and user-friendly control panel make it ideal for continuous snack food production.

Malaysian Noodle Snacks

Malaysian noodle snacks are crispy treats commonly enjoyed for their crunchiness and flavorful seasoning. Brands like Snek Ku are particularly popular, offering a variety of shapes and flavors such as spicy, chicken, and curry. These snacks are often designed to appeal to a broad audience, from children to adults.

Taiwanese Noodle Snacks

Taiwanese noodle snacks are a beloved treat, known for their crispy texture and rich flavors. One of the most iconic products in Taiwan is the "Everyone Says GOOD GOOD EAT" series by Wei Lih Food Company. These snacks have been a long-standing favorite in the local market, cherished for their satisfying crunch and versatile seasoning options.

Thai Noodle Snacks

Thai noodle snacks are unique in their presentation, often shaped like chicken legs, known locally as ขนมขาไก่ (Kanom Ka Gai). This distinct shape has become synonymous with fried noodle snacks in Thailand. Thai noodle snacks are known for their bold flavors, such as sweet and spicy or tom yum, reflecting Thailand's culinary heritage.

Applications

- Noodle Snack Production Line, Snack Noodle Production Line, Radish Cake Production Line, Winter Bamboo Shoot Cake Production Line

-

Malaysian Noodle Snacks

-

Malaysian Noodle Snacks

-

Malaysian Noodle Snacks

-

Taiwanese Noodle Snacks

-

Taiwanese Noodle Snacks

-

Thai Noodle Snacks

-

Thai Noodle Snacks

-

Thai Noodle Snacks

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machine manufacturer and supplier of Noodle Snack Production Line. From frying, drying and seasoning. We can provide complete Noodle Snack Frying production line solutions.

If you have a Noodle Snacks production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

-

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

As the global snack food market continues to expand, snack manufacturers face a critical challenge:...

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

The banana chips production line can be flexibly configured according to different product...

Details - Videos

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Noodle Snacks Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Noodle Snacks Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.

.JPG?v=1d0deffd)