Banana Chips Production Line Manufacturer

Banana Chips Production Line、Plantain Chips Production Line

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier. Providing the production equipment for banana processing, slicing, frying and seasoning of agricultural products.

The Banana Chips Production Line of TsungHsing Food Machinery (TSHS) uses banana as the raw material which is easy to obtain. It becomes the tasty snack and suitable for all ages after being washed, sliced and deep fried.

The raw material of the Banana Chips Production Line is fresh banana, and the banana aroma and taste crispness are optimized after the frying process. Therefore, the Banana Chips Production Line uses this feature to produce the banana chips by peeling the banana, frying and seasoning.

After being peeled, the banana will be sticky due to the feature of itself. Therefore, after peeling, it needs to be washed and then sliced. Generally, the slice thickness ranges are from 3 to 5 mm. Different slicers can be used optionally according to customers' needs.

After the banana is sliced, it can become semi-finished banana chips. After frying, it can optimize the aroma of the banana chips and make it taste crispy.

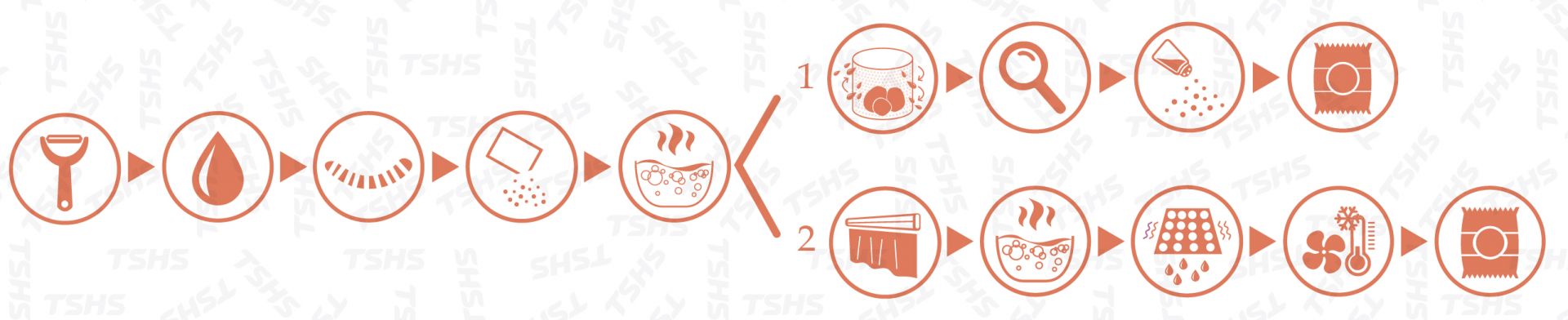

After frying, different seasonings can be made according to the needs of the customer's market. The following can be divided into the following two types:

1. Customers may just need the simple seasoning powder to taste, it is recommended to use the flavor powder sprinkler, the liquid sprayer and the rotary seasoning drum to make the seasoning powder fully adhere to the product.

2. Customers can also screen the fried banana chips first, then wrap the fried banana slices in sugar, and then fry the second time to obtain the fried banana chips.

Capacity

- In case of different products, please contact our business department and our staffs will be serving you.

Features

- Raw materials are easy to getting: Green bananas are more suitable for production, and production conditions vary depending on the region.

- No need for complicated procedures: After peeling, washing and cutting → frying → seasoning, it can be packaged for sale.

- It's easy to control and economize manpower by automatic production.

- The finished products have stable quality and meet the requirements of food hygiene regulations from integrated production.

Flow Chart

Peeling → Washing → Slicing → Quantitative Feeding → Frying→ De-oiling → Screening → Seasoning → Packing

Peeling → Washing → Slicing → Quantitative Feeding → Frying→Syrup Coating→Fryimg→De-oiling→Cooling→Packing

The photo of production

raw material: Peeling→

raw material: Peeling→

Green bananas are manually peeled after being sent to the factory.

(It's easy to cause lots of damage during the process of mechanical peeling because of the different size of bananas. )

Discharge:banana chips→

Discharge:banana chips→

actual production of high yield fried banana Chips

CASE STUDY

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

Details- Videos

- Finished Product Gallery

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Banana Chips Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Banana Chips Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.