Centrifugal De-oiling Machine

TsungHsing Food Machinery is a continuous de-fatting machine manufacturer and supplier. Centrifugal De-fatting, De-fat Machine, Centrifugal De-fat Machine

TsungHsing Food Machinery (TSHS) provides manufacturing equipment for large-volume, continuous de- oiling systems.

After frying, to reduce the oil content of the product, the surface and the oil inside the product can be removed by centrifugal de-fatting. The de-fatting system can be continuously connected in the front frying section to fully integrate the production line. Through the control of time, the production line can be completed without interruption.

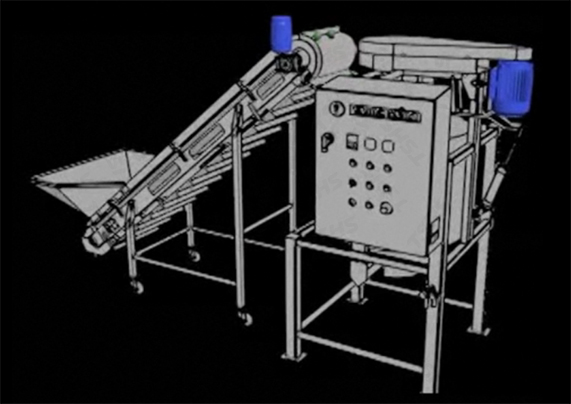

Complete de-fatting system, including automatic feeding (into the de-fatting) system, de-fatting main body, automatic discharging (outlet of the de-fatting) system. The operating principle of the de-fatting system is that the product after frying is quantitatively conveyed to the main body of the de-fatting, and the centrifugal force is generated by the rotation of the inner drum of the de-fatting, and the oil of the product itself and the surface oil are separated and pulled out. After the de-fatting is completed, the material is sent to the lower conveyor belt through the inner drum gate to advance to the next section.

Capacity

- The hourly capacity is determined by the amount of feeding per dispense and the de-fatting time each batch.

- Taking inflated food as an example, it can reach 300 kg/ hr of the production capacity, and the amount of de-fatting is different depending on the features of different products.

- Taking fried nuts as an example, it can reach 300 kg/ hr of the production capacity.

Features

- Adjustable de-fatting time and speed can be controlled according to product features.

- Generating centrifugal force to quickly separate excess oil adhering to the product by high-speed rotation.

- Small size, large capacity and easy operation.

- The whole machine is made of stainless steel, hygienic, and easy to wash.

- Fully automatic continuous operation for manpower economizing and stable, continuous de-fatting effect achieving.

- In the system, air knives and special accessories can be selected to complement the performance of different products.

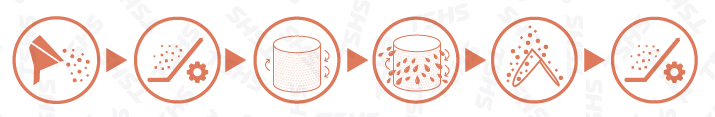

Flow Chart

The equipment usually connects to the previous process: continuous frying.

The de-fatting process is as follows:

Feeding into the Conveyor Hopper► Being Sent to the De-fatting Body Through the Conveyor► The Inner Drum Rotation Produced by the De-fatting Body► Rotation Produces Centrifugal Force and Separates the Oil► Completing De-fatting and Dropped into the Discharge Conveyor Hopper ► Being Sent to the Next Process Through the Conveyor

Product Features

- Complete de-fatting system, including automatic feeding (into the de-fatting) system, de-fatting main body, automatic discharging (outlet of the de-fatting) system. The operating principle of the de-fatting system is that the product after frying is quantitatively conveyed to the main body of the de-fatting, and the centrifugal force is generated by the rotation of the inner drum of the de-fatting, and the oil of the product itself and the surface oil are separated and pulled out. After the de-fatting is completed, the material is sent to the lower conveyor belt through the inner drum gate to advance to the next section.

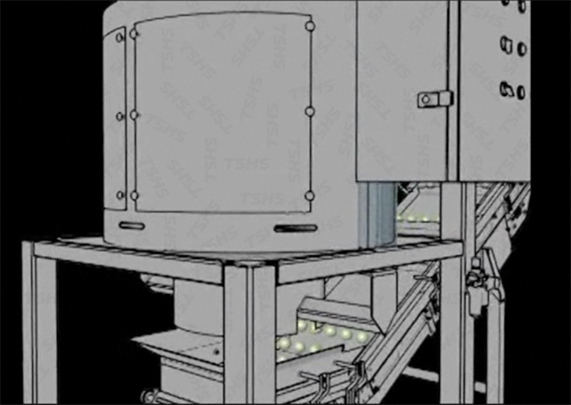

Principle of Centrifugal De-fatting Action

Details:

The feeding conveyor sends the product to de-fatting main body.

Generating centrifugal force to quickly separate excess oil adhering to the product by high-speed rotation in the main body of the de-fatting, achieving the effect of reducing oil content.

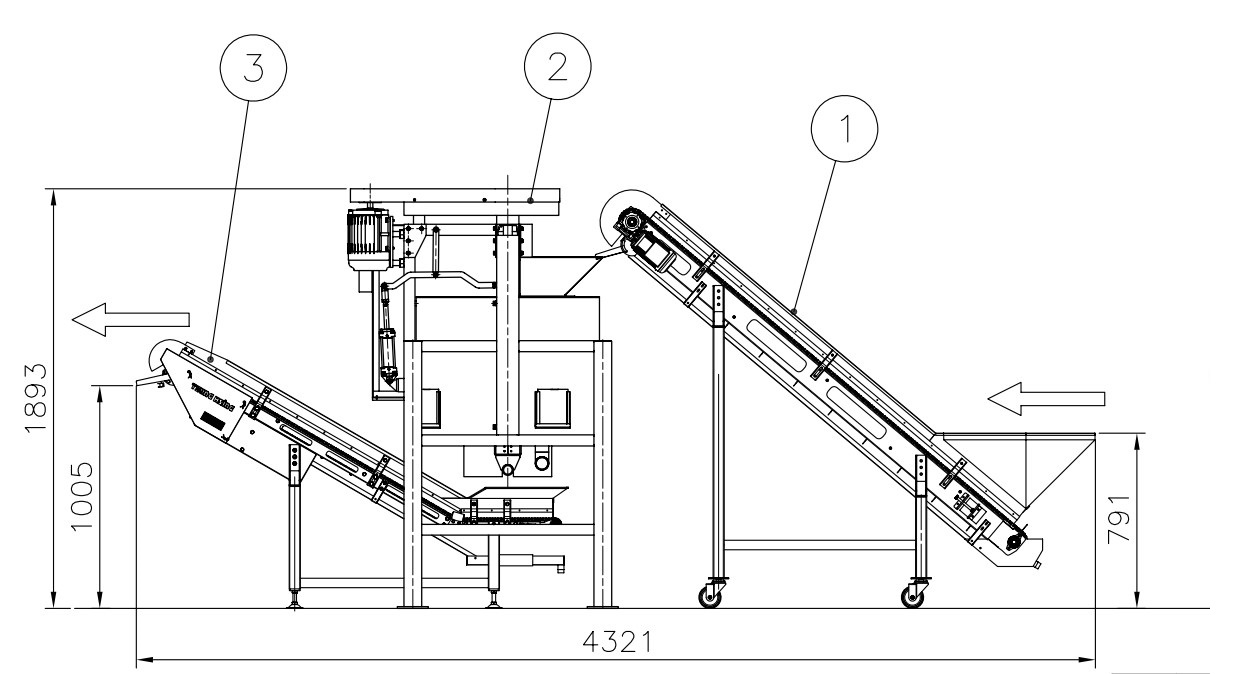

Specifications

| Machine | Product Description | Photo |

| 1. De-fatting Feeding Conveyor | Specification: Length 2350 x Width 690 x Height 1750 mm. Material: Using SUS304 in the structure of the whole machine except the motor. Horsepower Requirements: 1/4HP. Conveying Speed: With the fryer, you can set the automatic feeding rate and automatically run according to the setting. Conveyor Belt Material: Rod Mesh Belt. |

|

| 2. Centrifugal De-fatting | Specification: Length 950 x Width 1210 x Height 1750 mm. Material: SUS304 stainless steel. Effective Space of the Inner Drum: Length 700 x Height 300 mm. Horsepower Requirements: 2HP. Feeding Way: Feeding into the conveyor hopper of the feeding conveyor of the de-fatting. Running de-fatting: Two-stage speed control, according to product requirements, set the de-fatting time and automatically operate according to the setting. Discharging Way: The discharge plate is opened driven by the pneumatic cylinder, and the material is discharged from the lower part and automatically operated according to the setting. The discharge port is connected to the conveyor to prevent material from overflowing. Customers need to provide 3 HP air compressor by themselves. Capacity: Depending on the product's de-fatting time. |

|

| 3. De- fatting Discharging Conveyor | Specification: Length 1850 x Width 550 x Height 1060 mm. Horsepower Requirements: 90W. Conveying Speed: Constant speed. Conveyor Belt Material: SUS304 stainless steel. |

|

Peripherals / Accessories

Fryer

Product specifications can be adjusted according to the production line.

Applications

- Frying Products/ Puff Products/ Frying Nuts/ Snack Food/ De-fatting Application

- Related Products

-

Vibration Feeder

TsungHsing Food Machinery is a vibration feeder machine manufacturer and supplier. TsungHsing...

DetailsCentrifugal De-oiling Machine

TsungHsing Food Machinery is a continuous de-fatting machine manufacturer and supplier. Centrifugal...

DetailsContinuous Fine Filter

TsungHsing Food Machinery is a Continuous Fine Filter machine manufacturer and supplier. TsungHsing...

Details - Product catalog Download

-

Peripheral Equipment_De-oiling Machine Digital Catalog

The purpose of the centrifugal de-oiling machine for food is to drain the excess oil in the food to maintain the taste of the product and prolong the fresh-keeping...

Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Centrifugal De-oiling Machine Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Centrifugal De-oiling Machine supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.