Grain Puff Production Line Manufacturer

Baked Extruded line, Corn Snack Extruded Line, Direct Expand Extruded Line, Popper Production Line, Cheese ball Production line, Puff corn Production Line, Corn Cracker Production Line, Thai Roll Snack Production Line, ขนมข้าวโพดอัดแท่งแบบแบน, ขนมข้าวโพดอัดแท่ง, ขนมข้าวโพดอัดแท่งสไตล์ญี่ปุ่น, 泰國捲生產線, 米果捲生產線, 乖乖生產線, Corn Snack Fryer

Our corn curl production line is fully automated, it is easy to operate and manpower saving. The machine is stainless steel made, it is easy to clean and conform to food hygienic standards. Grinded rice, corn, or grains could serve as raw material. Through mixing, extruding, cutting, drying or baking, seasoning process, delicious product will be produced.

Corn curl is the most popular snack food all around the world. By replacing the extrusion mold, you can produce products in various kinds of shape. And by using filling machine, you can produce filled puff product to enhance the flavor. From raw material pretreatment to semi-product extruding and seasoning, we can help you design and make the whole production line with our expertise.

Features Of Grain Puff Production Line

1. Easy to control by automatic production line.

2. Optional fillings for cooking makes it easy to prepare all of the raw materials.

3. Using the corn or rice mash as the raw material, having the benefit of easy to getting and low-budget.

4. No wasting from being fully utilized of the raw materials.

5. The raw material mixer can be used in one-to-two with cereal burst machine, saving equipment investment cost.

6. Provides moisture meter to measure the moisture content of raw materials before and after humidification.

7. Good taste from single-axis spiral extruding and leavening.

8. Adjustable feeding speed according to the production requirements.

9. Variety of different shape product by replacing mold easily.

10. The cutting device of the extruder has a cover to ensure safe operation.

11. Adjustable baking or drying temperature and time.

12. Equipped with the temperature display and control device.

13. Insulation device to improve thermal efficiency.

14. Optional round and rectangular product cutting machine according to the requirements.

15. The liquid sprayer has electric heat insulation to maintain liquid fluidity.

16. The powder sprinkler feeds the seasonings with a screw, and the amount of powder can be adjusted according to the requirements.

17. Integrated, safe and hygienic seasoning drum.

18. The equipment of the whole production cycle is made of stainless steel which is hygiene and easy to clean.

Process

Raw Material Mixing and Humidification → Shape by Spiral Extruding (if it is with filling, the filling is done at the same time as the extrusion) → Baking or Drying → Liquid (Oil) Sprayer → Seasoning → Cooling → Packing

(This is the basic configuration, please contact us for other special processes.)

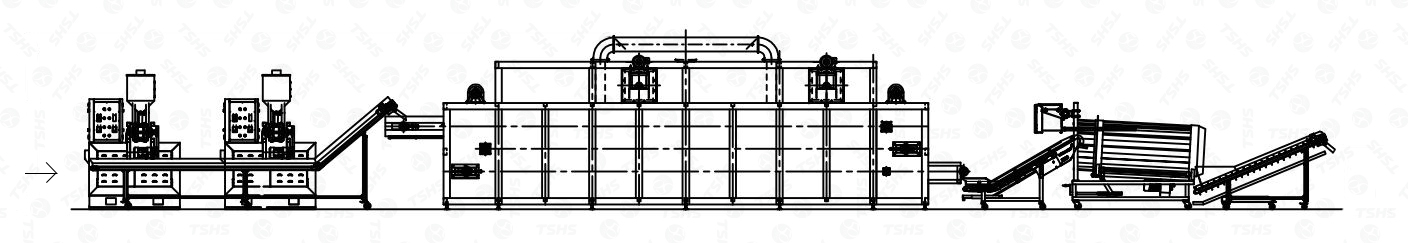

Machine Layout

Equipment Information Of Grain Puff Production Line

1. Humidifying Mixer

the first stage of the production of Grain Puff is the mixing of raw materials, with normal temperature, clean water and raw materials such as rice, corn mash, or other grain mixed to a moisture content suitable for extrusion. The humidifier equipment in the Grain Puff Production Line of THSH have vertical and horizontal forms, which are used according to the raw materials used by customers. Specification: Length 1200 x Width 1200 x Height 1500 mm. Function: The raw materials are mixed with an appropriate amount of water according to the required water content and sent to the cereal burst machine. Horsepower Requirements: 3 HP. Features:(1) Vertical Mixing. (2) Saving equipment investment cost by one-to-two collocation and the automatic production line.

2. Grain Puff Extruder (Cereal Burst Machine)

The cereal burst machine of the Grain Puff Production Line is a single-axis spiral structure, with the design of the mold produce the required shape. The mixer sends the raw material to the storage drum of the cereal burst machine, and the mold is heated by electric heating. When the temperature reaches the required temperature, the extrusion starts, the product expands due to the friction of the high temperature and the spiral pressure, and the product is semi-cooked during the leavening process. Products without filling can be cut directly at the exit of the mold according to the required length. The cutting machine has a protective cover to ensure safety. It also has the features of adjustable feeding speed and cutting speed, which can be continuously operated, less loss of raw materials, simple operation and convenient maintenance. The mold can be replaced, and the same production line can produce a variety of products with high economic benefits. Specification: Length 1800 x Width 1800 x Height 2000 mm. Function: The semi-cooked product shaped by spiral extruding and leavening process. Horsepower Requirements: 25 HP. Features:(1) Good taste from single-axis spiral extruding and leavening. (2) Suitable for granular raw materials.

3. Filler

The filler of the Grain Puff Production Line is an optional equipment and is only used in products with fillings. The filler has a double-layered pot to store the stuffing, the interlayer has insulation to prevent the filling from solidifying, and the filling is connected to the extruder through the metal hose by the pump, and the filling is injected into the product while the product is extruded and not yet solidified to add flavor and taste. Specification: Length 1200 x Width 720 x Height 1500 mm. Function: The filling is simultaneously injected into the product during the leavening process. Features:(1) Adjustable filling amount. (2) Product taste and diversity optimization. Horsepower Requirements: 3 HP.

4. Cutting Machine

The cutting machine of the Grain Puff Production Line of THSH has a round and a rectangular product cut, which are used in products with filling. Mainly to control the length of the product, the round product is controlled by the spacing between the die-cut molds. The rectangular product is first flattened by rounding the product, and then control the required length by adjusting the cutter and the feeding speed. Specification: Length 2700 x Width 830 x Height 1520 mm. Function: Cut the product to the ideal length. Horsepower Requirements: 1 HP. Features: (1) Optional round and rectangular product cutting machine according to the requirements. (2) The length of the round product can be changed by the changeable spacing between the die-cut molds. (3) The length of the rectangular product can be controlled by speed adjusted.

5. Infra-Red Tunnel Oven

The oven of the Grain Puff Production Line is mainly used for filling products, tunnel design, There has conveyor and leveling device to spread the product evenly on the conveyor inside, and use infrared fire tube as heating medium. Located above and below the conveyor, each fire tube is independently controlled by turning on and off. The firepower can be adjusted according to the product requirements. The unique penetration of the infrared fire tube is used to make the product evenly heated, and the flavor is unique and crispy. The heating zone of the oven is equipped with a heat preservation device, which can keep the heat energy in the machine, saving energy and having friendly working environment. Specification: Length 8500 x Width 1350 x Height 1800 mm. Function: With infrared heat into the product is cooked crispy products. Horsepower Requirements: 1 HP. Features: (1) Suitable for products with fillings, the cooking temperature is higher. (2) Using gas as a fuel, and baking crispy products by infrared penetrating. (3) Adjustable baking time.

6. Conveyor Type Auto Dryer

The conveyor type auto dryer is used in products without filling. The temperature is lower than that of the oven. The dryer can be a single-layer or multi-layer conveyor. It is prepared according to the output and drying time. The air is heated by the burner and the hot air is sent to the drying area for circulation by windmill. The drying temperature and drying time can be set according to the product requirements. The heating zone of the dryer is equipped with a heat preservation device, which can keep the heat energy in the machine, saving energy and having friendly working environment. Specification: Length 9500 x Width 2400 x Height 2600 mm. Function: The product is cooked into a crispy product by hot air. Horsepower Requirements: 10 HP. Features: (1) Suitable for products without fillings, the cooking temperature is lower. (2) Multi-layer conveying, the product can be turned over and evenly heated. (3) Adjustable baking time and temperature.

7. Seasoning System

The seasoning system of the Grain Puff Production Line of THSH is composed of a liquid (oil) sprayer, a powder sprinkler and a seasoning drum. In the pump, the seasoning liquid or oil is sprayed on the product through the nozzle, so that the product has the appropriate humidity to absorb the seasoning powder. The seasoning powder is spiral and quantitative feeding to the seasoning drum, so that the product and the seasoning are evenly mixed when the seasoning drum is turned over, thereby increasing the flavor of the product. The seasoning drum of the Grain Puff Production Line is integrally formed, hygiene and easy to cleaning, and can be applied to various snack foods, which is an indispensable part of food processing. Specification: Length 3000 x Width 3000 x Height 1800 mm. Function: Adding seasoning powder to make delicious potato chips according to the ideal taste. Horsepower Requirements: 5 HP. Features: (1) Three-in-one device consisting of sprayer, powder sprinkler and seasoning drum. (2) Using the spray liquid to moisten the surface of the product, and then mix the seasoning powder into the seasoning drum for mixing.

8. Discharge Conveyor

The conveyor is used to deliver the seasoned product, which has a cooling effect on the one hand, and can be automated connected to the packaging system, economizes manpower, increases hygiene and maintains product quality on the other hand. Specification: Length 2000 x Width 800 x Height 1200 mm. Function: Quantitatively delivering the seasoned Grain Puff products. Horsepower Requirements: 1/2 HP. Features: Can be automated connected to the packaging system according to the requirements.

Capacity

- 100 kg/hr (GP100)

- 200 kg/hr (GP200)

- 300 kg/hr (GP300)

Applications

- Puffed Grain Snacks, Puffed Corn Snacks, Rice Rolls, Guai Guai (Taiwanese Snack), うまい, Corn Sticks, can be produced in various shapes to meet specific product requirements.

- Tohato Caramel Corn (Japan)

- Spherical

- Puff Corn

- Different Shape Grain Puff

- Filling Bar

- Corn Bar Snack

- Square Filled Rice Crackers

- Star-shaped

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machine manufacturer and supplier of Grain Puff/Corn cracker Snack Production Line. From raw material mixing, filling, roasting(baking), and seasoning. We can provide complete Corn Puff Snack production line solutions.

If you have a Grain Puff production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details- Videos

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Grain Puff Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Grain Puff Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.

Puff Extruder_800x450.png?v=53cc06d2)