Corn Curl Production Line Manufacturer

Cheetos Production Line, Kurkure Production Line, Corn Curl production line, Cheese curls, Cheese Puff, ขนมชีโตส, スコーン, Cheetos Fryer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around the world currently. After the processing of extruding, molding, frying and seasoning, it can be produced corn sticks that are suitable for all ages and really delicious. Tsung Hsing provides the whole plant planning solution for the corn curl production line from pre-processing mixing and extrusion of corn raw materials to frying and seasoning.

The raw material of the corn curl production line is corn crumbs that cause a special characteristic when mixed with water. That will become thick and hard by quick hit, but not by slow collision. Therefore, the corn curl forming process is heating the mixture of corn grits and water and then extruding them by mold.

Because of the corn grits steam inside contacts with air increases the volume of the Corn Curl and to be extruded. Finally the crispy Cheetos corn curl can be produced by frying and seasoning. This product is widely used in snack food all over the world. It also named Twisty, Cheetos, Kurkure, Corn Curl.

Features Of Corn Curl Production line

1. The raw material is easy to get: Corn Grit + Water were pressurized heat through friction, then shaped and extruded by the air ingress.

2. Simple productive process: Shaping and extruding → Frying → Seasoning, then packaging for sale.

3. Easy to control and economize manpower by automatic production line.

4. Stable quality of the Corn Curl Product from integrated production, and it compliances the law on food hygiene.

Process

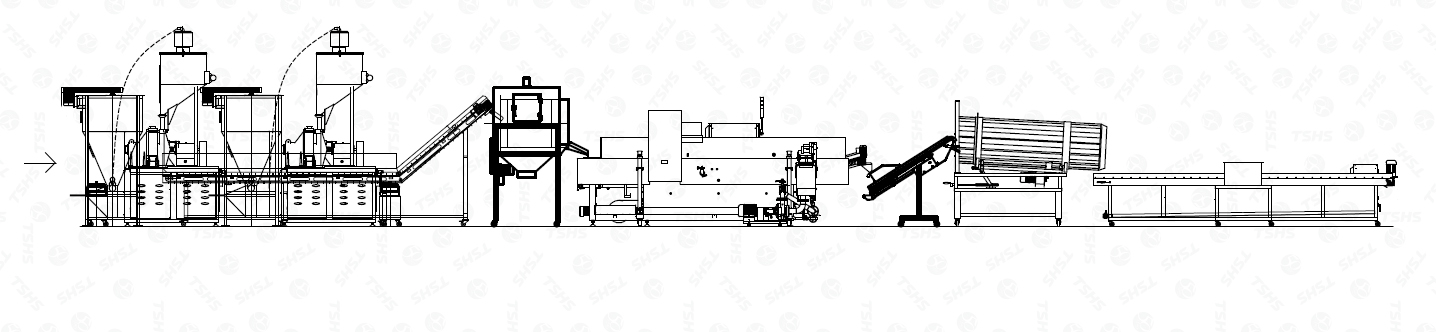

Mixer → Feeder → Extruder → Screening → Quantitative Feeding → Oil Fryer → Seasoning → Cooling Conveyor → Packing

Machine Layout

Equipment Information Of Cheetos Production Line

1. Mixer

Raw Material Mixing and Humidification: For the humidity of general commercially available corn flour raw materials are about 12~13%, the raw materials need to be uniform mixed with water to reach the humidity 15~16%.

2. Feeder

Vaccun Feeding Machine: The humidified mixture of good corn raw materials, sent to the extruder.

3. Product Molding

Extruder: Mixed corn grit, which is sent from the extruder bucket to the composite millstone by screwing through the extruder, after molding the product is semi-finished products.

4. Screening

Screening machine: The semi-finished products will be the initial screening, will be too small semi-finished products in this first screening out to stabilize the quality of finished products after frying.

5. Quantitative Feeding

Quantitative Feed Machine: The use of vibration to semi-finished products into the frying machine in order to avoid frying due to the amount of material into the oil temperature.

6. Frying and Cooking

Continuous frying machine: The selected corn strips are sent to the fryer for frying, and the fryer of TSHS has the characteristics of two highs and three savings which can be stabilized early and filtration systems designed for agitating blade corn oil plus strip, so that products can reach 200 to 300 kg/ hr of the production capacity. The general temperature setting is about 170-190 ° C when frying, and the frying time is from 40 to 90 seconds, depending on the raw materials.

7. Conveyor

Conveying process of Corn Curl(Kurkure, Cheetos) followed by seasoning system after frying.

8. Seasoning

Rotary Seasoning Drum: Modest seasoning after sent the fried Corn Curl to the rotary seasoning drum according to local taste. If the customer only needs simple seasoning powder seasoning, it is recommended to use the flavor powder sprinkler, the liquid sprayer and the rotary seasoning drum to make the seasoning powder being attached to the product. If the customer needs to mix the seasoning powder with the seasoning liquid, it is recommended to use the spray mixer and the mix of barrels, so that the seasoning liquid can be attached to the product.

9. Inspection Cooling

Cooling Conveyor: After the seasoning of the product temperature is still about 70 to 80 degrees, the use of cooling conveyor can effectively cool the product temperature (about 40 to 50 degrees) to facilitate the back into the packaging machine, and can use the cooling conveyor to do product testing, here With the artificial sale of poor products will do the final screening shave to get the best product.

Capacity

- 110kg/hr (KK-110)

- 220kg/hr (KK-220)

- 330kg/hr (KK-330)

- In case of different products, please contact our business department and our staffs will be serving you.

Product Features

- Compared with other production lines, the Corn Curl Production Line is easier to control, low investment, large output value, and high profit. It is all about whether the enterprise can seize market opportunities and use the Corn Curl Production Line to start profit-earning investment.

Peripherals / Accessories

- Fryer Accessories (optional).

- Scraping at the Bottom.

- Online Fine Filter.

- Vacuum Oil Water Separator.

- Oil Cooling System.

- Oil Drum Insulation / Cooling System.

- Seasoning System.

- Corn Curl Extruder Accessories (optional).

Applications

- Snack Foods, Corn Curl, Cheetos Products,Kurkure,Nik Nak Line.

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machine manufacturer and supplier of Cheetos Corn Curl Production Line. From raw material extrusion molding, puffing processing, frying and seasoning. We can provide complete cheetos corn stick production line solutions.

If you have a Cheetos production machine requirement, please fill out the inquiry form below.

We will contact you as soon as possible.

- Related Products

Grain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

The noodle snack frying production line features fully automated continuous fryers and advanced...

DetailsGreen Pea Production Line Manufacturer

The most worrying customers are the quality of the products during the production of Frying...

DetailsPotato Chips Production Line Manufacturer

The potato chips frying production line provides a fully automatic and continuous solution...

DetailsFish Shred Production Line Manufacturer

The fish shred production line uses fish paste as its primary raw material and processes it through...

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details- Videos

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Corn Curl Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Corn Curl Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.