Conveyor Belt Continuous Dryer Equipment

Belt Dryer、Conveyor Type Auto Dryer、Continuous Dryer、Multi-Layers Dryer、Industrial Tunnel Dryer、Single-layer Drying Machine

TsungHsing Food Machinery is a conveyor type auto dryer machine manufacturer and supplier. TsungHsing Food Machinery (TSHS) provides continuous, large-volume, water-reducing drying equipment manufacturing. Can be applied to food, pharmaceutical, industrial and other drying requirements.

The used energies of conveyor type auto dryer of TSHS are: Natural gas (LNG), Liquified Petroleum Gas (LPG), steam, electric energy and other energy sources. Automatic temperature control after temperature setting. It is meet the requirements of food hygiene regulations and easy to repair.

It is suitable for the drying of snack foods: for example, grain and soy protein products (commonly known as vegetarian meat), kuai kuai, corn curl, fish shred, nuts, dried fruit and so on. Agricultural and fishery products: such as dried fish, dried sea shrimp, orange daylilies, mushrooms and other products, such as drying, can be based on product features, planning, operation. The temperature can be set and the mesh belt speed drying time can be adjusted to dry the product evenly. Now used in various major food factories.

The conveyor type auto dryer of TSHS is divided into: the feeding section, the drying section, the hot air generating chamber, and the discharging section. The equipment is meet the requirements of food hygiene regulations, automatic constant temperature control, and the parts exposed to food are made of stainless steel.

Description of the Yield: According to the proportion of the dried objects, the stackable feature, the drying time water content, the drying temperature, the available space for the equipment, etc.; to determine the length of each layer of the conveyor belt and the number of layers required to determine the size of the equipment. TSHS has standardized the size of the equipment according to the " conveyor type auto dryer ", such as mesh belt width, length, layers amounts and other standard specifications for customers to choose. The amounts of layers according to the mesh can be divided into: 3, 5, 7 ~ 11 layers, the length is more than 6M, and the device length is determined by 2M.

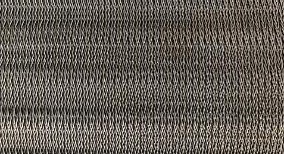

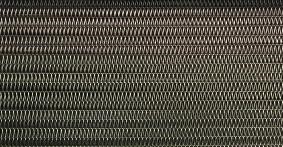

| Description of Chain Mesh Belt Types: It can be selected according to the size or features of the product to be dried, such as stainless steel rod mesh belt, rhombic steel, woven steel, flat belt, perforated metal panel or multiple combination. | |

|  |

| Perforated Metal Panel | Rhombic Steel |

|  |

| Woven Steel/ | Rod Mesh Belt |

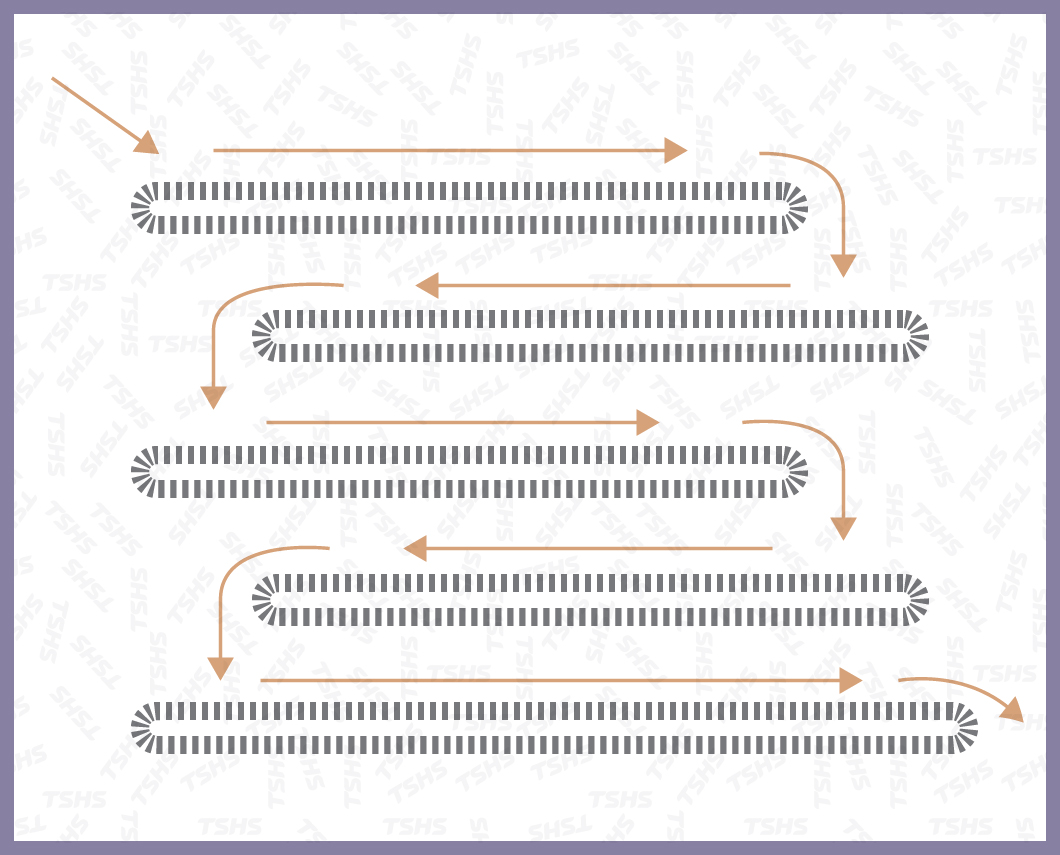

The object to be dried is fed from the uppermost first layer of the feeding section, and can be matched with the vibration feeder or the blade type leveler before the feeding, and the dried material is evenly laid on the mesh belt. After that, it is turned down from the upper layer to the next layer, which can be loosened, separated or turned over. A guide plate can be arranged between the layers to make the dried objects evenly spread on the lower mesh belt. After the drying is completed, the discharging section discharges and is connected to the next process.

Feeding →Discharging Process | |

| |

| |

Description of Drying Section:

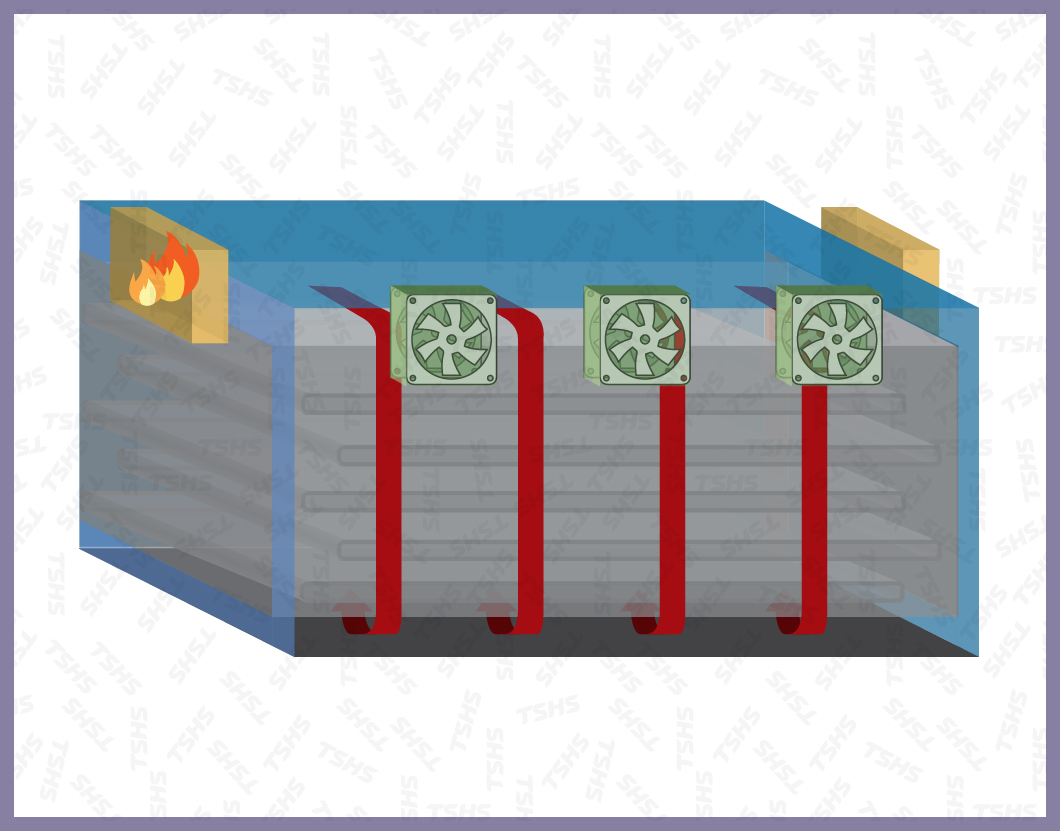

Automatic temperature control after temperature setting. The upper layer is a hot air generating chamber. For example, the energy is gas: the combustion chamber is burned by the end of the chamber to generate hot air. The chamber is divided into sections according to the length, and the circulating blowers are arranged on the sides of each section, and each section is staggered before and after, and the hot air is sucked through the blower. Blowing down, the hot air is sent to the drying chamber through the air passage, and the dried objects are dried. The remaining hot air can be recycled.

The Energy is Electric or Steam:

Each segmented chamber temperature is set by an independent electronically controlled electric heating rod or a steam heat exchanger to generate hot air, which is sucked through a blower and then blown down, and the hot air is sent to the drying chamber to dry the dried objects. The remaining hot air can be recycled. A moisture exhaust blower is arranged on the outer part of the drying chamber, and the exhaust frequency and the exhaust time can be set according to the product features.

The moisture in the drying section is discharged outside the equipment. The left and right sides of the drying chamber are provided with inner and outer door panels, the inner door is used for air duct diversion, and the outer door panel is provided with insulation layer to prevent heat energy loss. The door panel can also be opened to facilitate the washing and maintenance of the mesh belt and the drying chamber.

Description of the Optional Device:

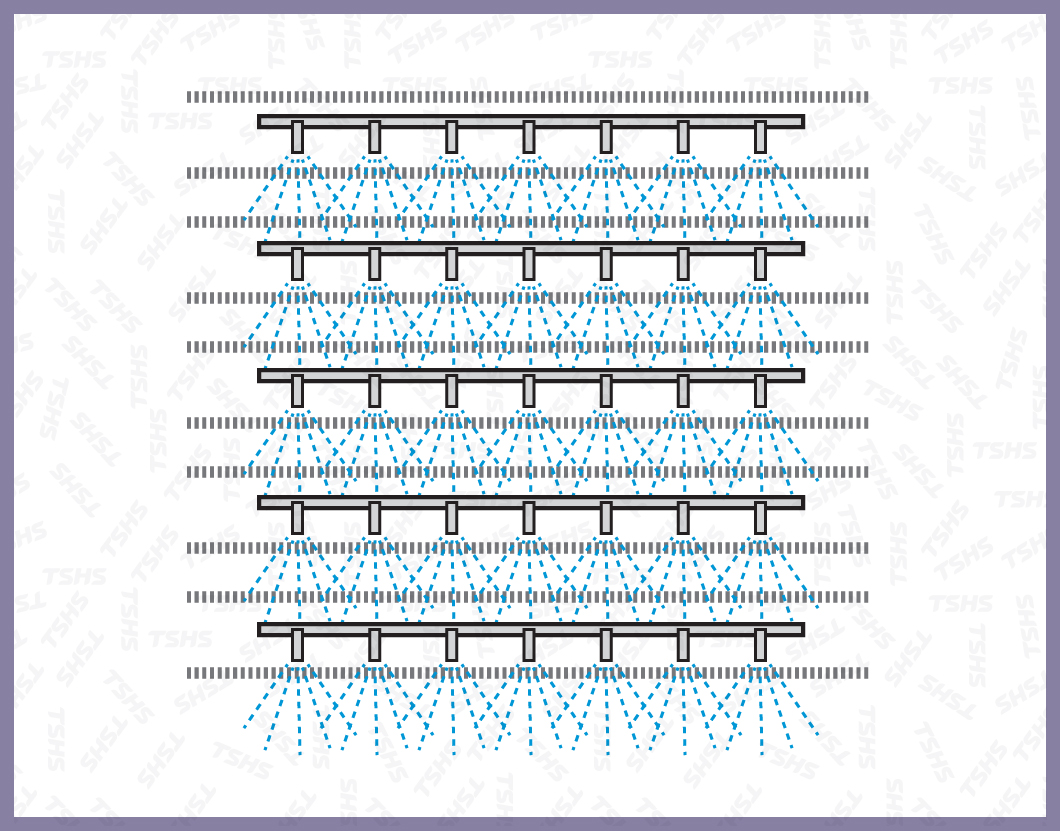

According to the features of the dried objects, the inner exit side of the drying section, in the middle of each layer of the mesh belt, an automatic sprinkler is provided, and the sprinkler can be started automatically or manually, and the mesh belt is adhered. A bottom plate is arranged at the bottom of the drying chamber to concentrate the drainage of the waste water. A cleaning device can also be arranged in the inner bottom plate of the chamber, which can collect the dust and dust falling off when the dried objects are dried, being collected by a small drawer and manually cleaned regularly.

Capacity

- Different planning and design according to the customer's product features and yield is available after the further contacting with our company personnel.

- The amounts of layers according to the mesh can be divided into: 3, 5, 7 ~ 11 layers, the length is more than 6M, and the device length is determined by 2M.

Features

- The whole machine is made of stainless steel, which is beautiful, hygienic and durable.

- The energy of the drying equipment can be selected according to the customer, just like natural gas, barrel gas, electric heat, and steam, etc.

- The hot air in the drying chamber is placed on both sides, and the objects are dried evenly.

- Saving energy by insulating the thermal insulation device on the outer plates of the drying chamber.

- Both sides openable door design for friendly cleaning, maintenance, inspection and economizing manpower.

- To deal with the sticking problem by scrap material, there is optional automatic washing device, and the mesh belt can be washed automatically after drying.

- The cleaning waste water has centralized treatment and drained to economize the cleaning manpower.

- The burner ignition start sequence has a foolproof design to avoid faulty operation.

- The equipment can be stopped immediately in necessary by the emergency stop button set on the front and rear ends of the dryer.

- Having automatic constant temperature control system of the dryer, which can adjust the drying temperature according to the product.

Flow Chart

Feeding → Conveyor Type Auto Dryer → Discharging → Seasoning → Cooling

Product Features

- The material is fed in a continuous manner, and the dried product is dehydrated by hot air to achieve the purpose of drying. Since the drying chamber conveyor belt has a multi-layer type, when the lower layer web is dropped from the upper layer, it can be automatically inverted to achieve homogenization.

Equipment Information Of Related Product

- Basic specifications are the same as our specifications sheet. The amounts of layers according to the mesh can be divided into: 3, 5, 7 ~ 11 layers, the length is more than 6M, and the device length is determined by 2M.

- Different planning and design according to the customer's product features and yield is available after the further contacting with our company personnel.

Advantages:

1. Product dryness is uniform.

2. According to the demand of the product, it can be matched with the suitable conveyor belt type.

3. Automatic temperature control after temperature setting.

4. Single-layer three-turn drying machine, The automatic washing device on the belt line is a special design and needs to contact the business personnel of our company.

Peripherals / Accessories

- Feeding M/C

- Swing Conveyor

- Seasoning System

- Cooling M/C

Applications

- Snack Food Drying, Fruit Drying, Drying after Seasoning, Plain Meat Drying, Nut Drying

Differences:

1.Generally, the traditional small-volume production uses the “Cabinet Type Dryer”. The dried objects are placed on the support plate, and the trays are placed on the trolleys in turn. The trolleys are dried in the push-type drying chamber, because of the problem of uneven temperature distribution in the chamber. It’s necessary to take out the pile and continue to dry depending on the dried materials. After drying, do the opposite. The whole process is labor-intensive, time-consuming and inefficient.

2.The conveyor type auto dryer generally uses the feeding conveyor, automatic quantitative feeding. If you need to match the wide width dryer mesh belt, you need to cooperate with the swing conveyor, then the dry objects can be automatically distributed evenly in the dryer net belt. The belt is automatically dried into the drying chamber according to the speed of the belt.

3. Automatic temperature control after temperature setting without escape corner.

4. Suitable for mass production by the features of automatic production and manpower economizing.

- Related Products

Conveyor Belt Continuous Dryer Equipment

TsungHsing Food Machinery is a conveyor type auto dryer machine manufacturer and supplier....

DetailsContinuous Microwave Hybrid Dryer Equipment

Tsung Hsing and Industrial Technology Research Institute cooperate in research and develop...

DetailsCabinet Type Dryer Equipment

TsungHsing Food Machinery is a cabinet type dryer machine manufacturer and supplier. TsungHsing...

DetailsInfrared Drum Dryer Equipment

Infrared dryer drums use radiation to transfer heat to the targeted object, eliminating the energy...

Details- Videos

- Finished Product Gallery

- Product catalog Download

Industrial Dryer_Continuous Conveyor Dryer Digital Catalog

The industrial conveyor belt dryers are suitable for various industries with drying, dehydration, roasting, baking...etc. It can be automated or connect...

Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Conveyor Belt Continuous Dryer Equipment Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Conveyor Belt Continuous Dryer Equipment supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.