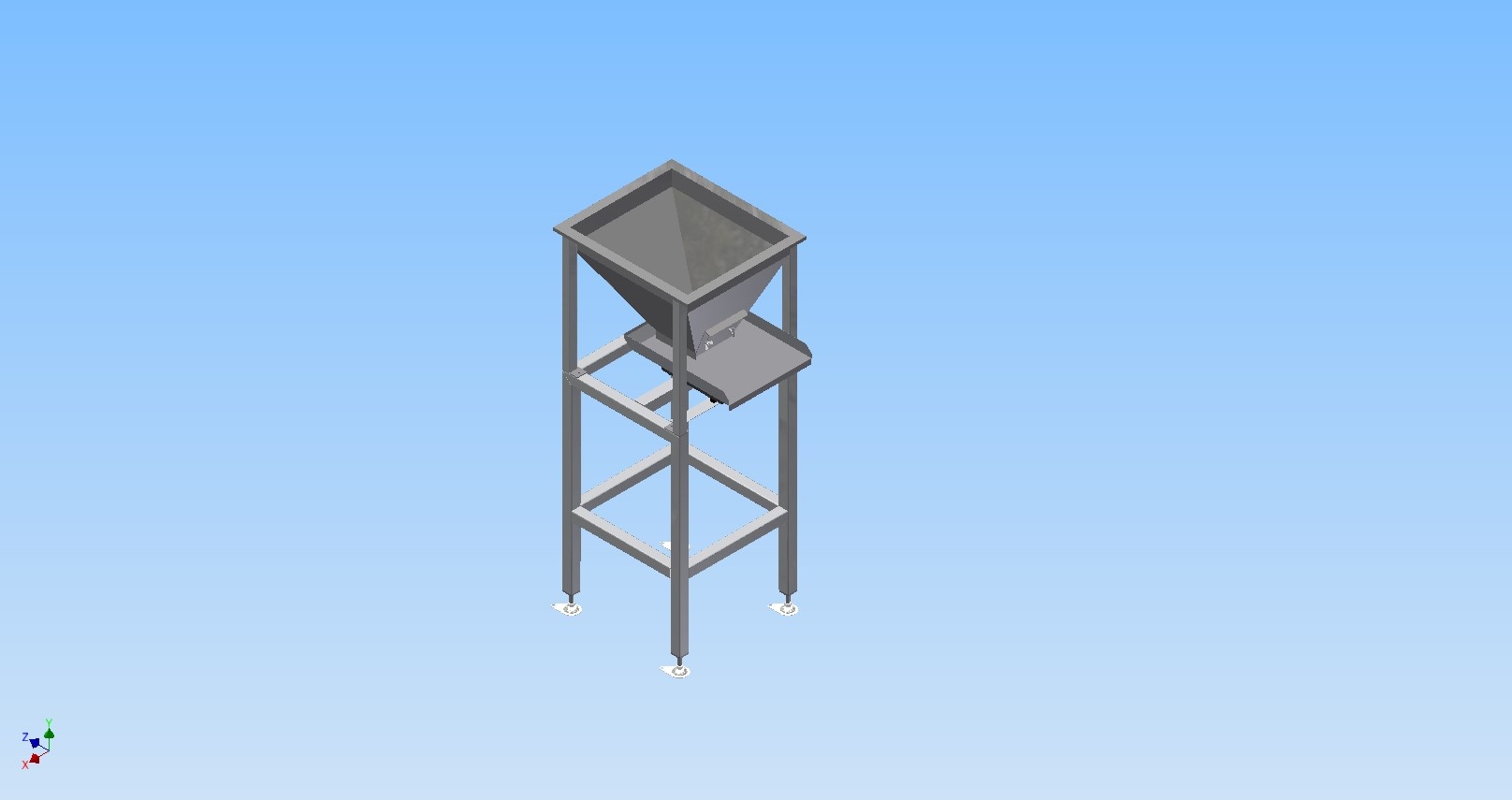

Vibration Feeder

Vibration Feeder, Feeder

TsungHsing Food Machinery is a vibration feeder machine manufacturer and supplier. TsungHsing Food Machinery (TSHS) provides continuous feeding system equipment manufacturing.

The vibration feeder mainly distributes the raw materials evenly and quantitatively on the connected equipment by vibration. According to the equipment of TSHS, it is usually connected with the fryer, which is suitable for the features of small size, light weight and non-stick products, such as green beans and Pellet, can reduce the temperature change during the frying process due to the quantitative feeding of the product, and the product can be evenly ripened to ensure stable quality.

Description

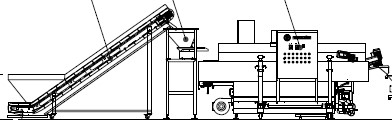

The vibration feeder of TSHS is connected to a feeding conveyor in the front section, and then connected to the continuous fryer.

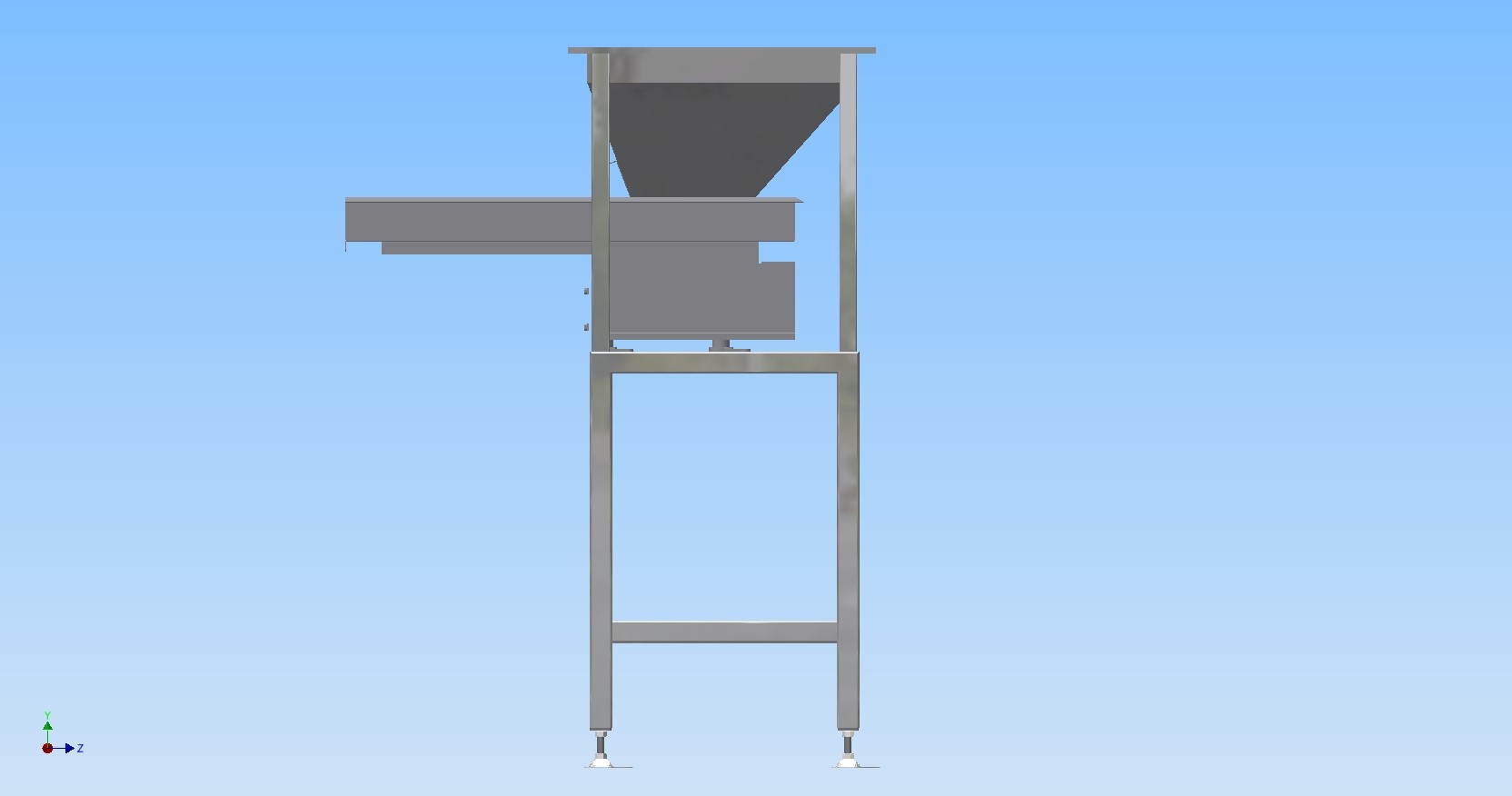

| Machine Description | Photo |

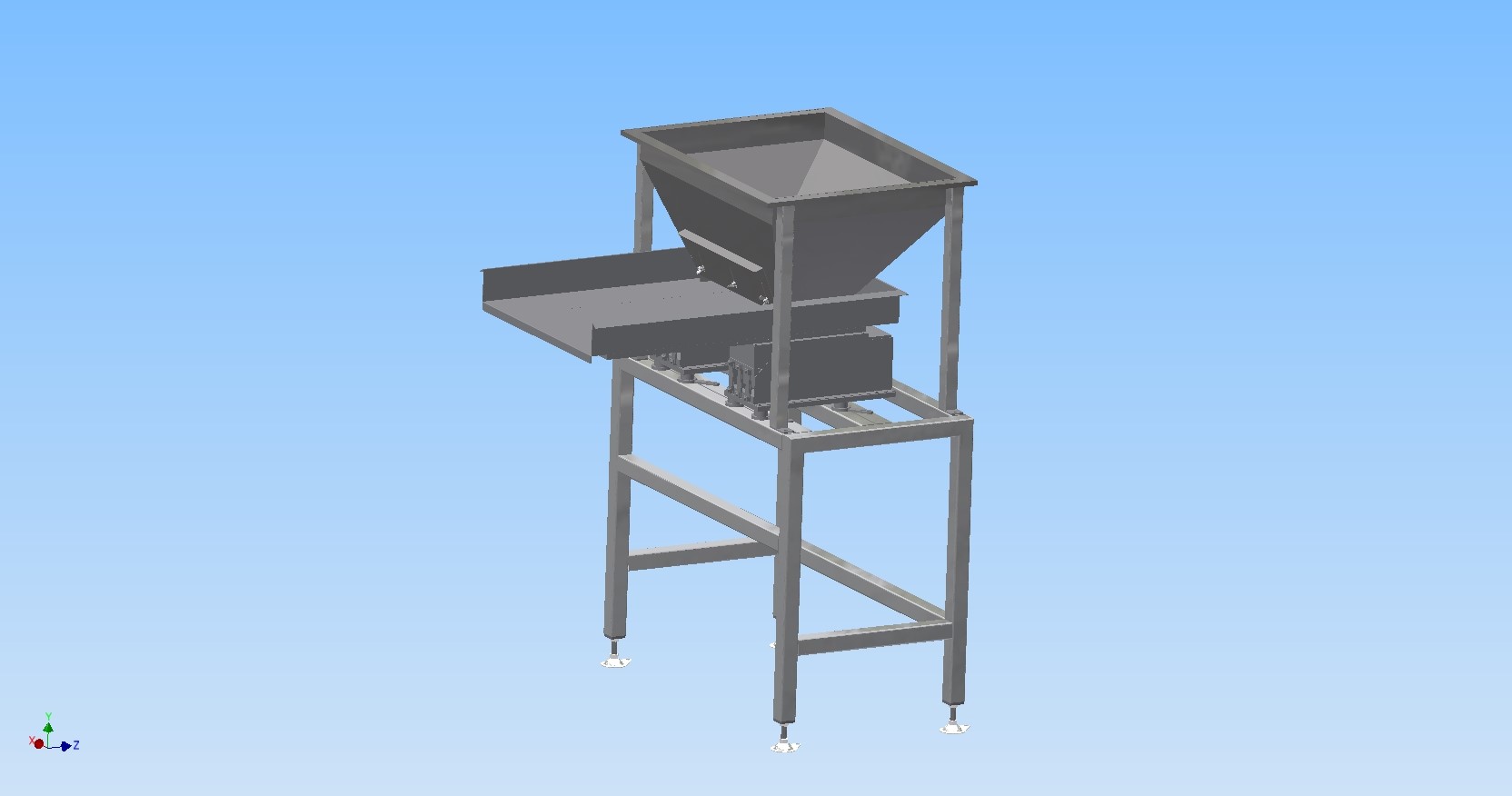

| A. Feeding Conveyor in the Front Section: The front section is usually matched with a plastic steel conveyor belt. The purpose is to centralize the raw material transportation on the hopper of the vibration feeder. Compared with the hopper directly fed by the operator, it is easier to operate with the plastic steel conveyor, and the feeding amount control is more Stable; at the same time, the plastic steel conveyor can increase work efficiency by the easy operation, cleaning and maintenance. |  |

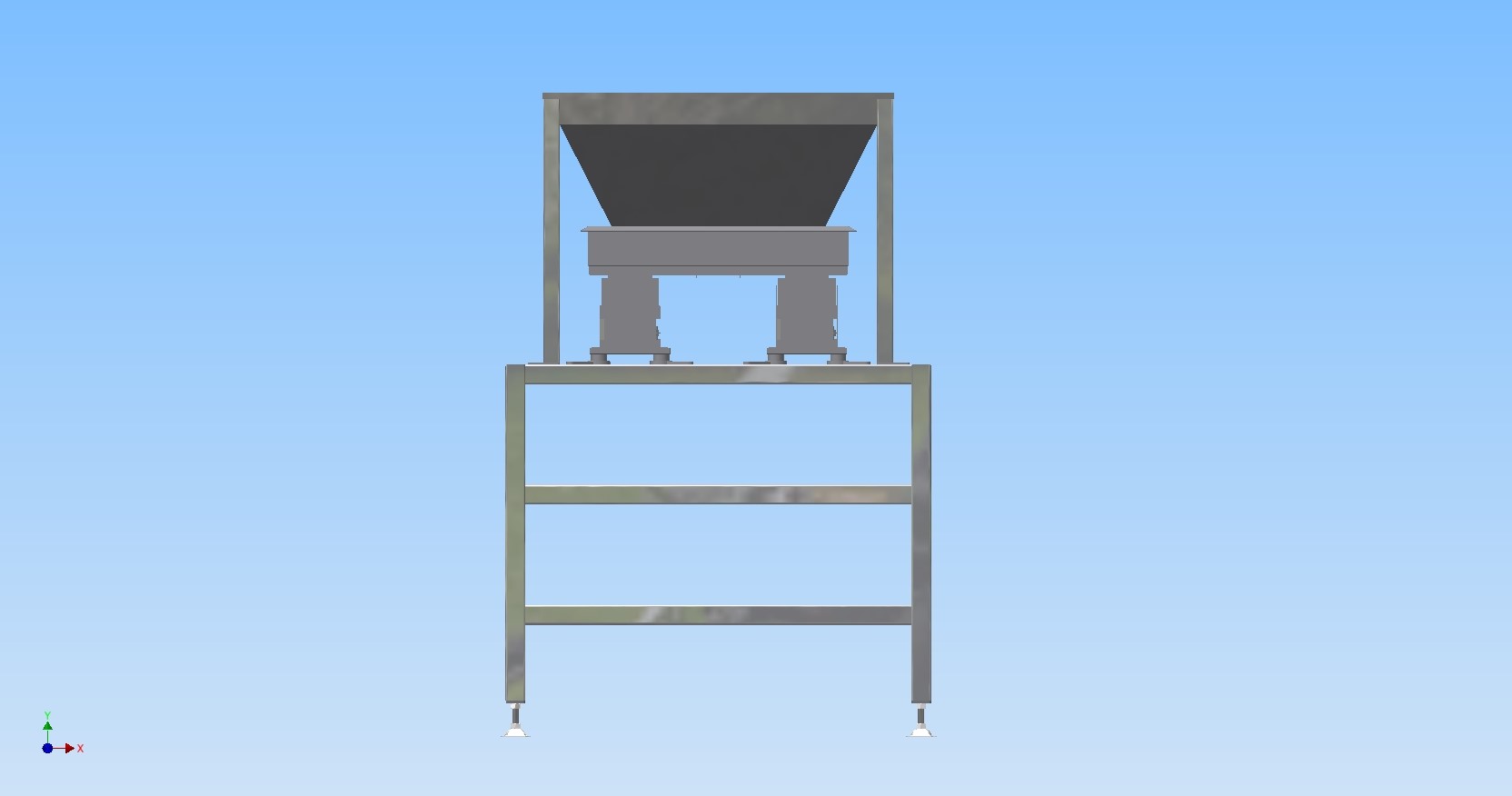

| B. Vibration Feeder: After the raw material enters the hopper of the vibration feeder by the plastic steel conveyor, it is centralized in the temporary storage space in the hopper. The operator can change the feeding speed by adjusting the vibration frequency, the strength and the opening degree of the discharging gate. |  |

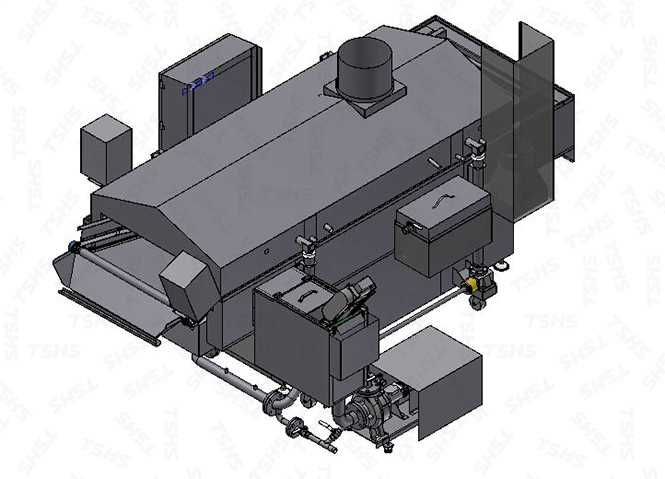

| C. Continuous Fryer: The features of the fryer of TSHS are high heat exchange rate and stable frying temperature. Therefore, the optimum yield and quality can be achieved by adjusting the speed and quantity of the feeding and the frying temperature and time of the fryer. |  |

Features

- Evenly and stable feeding.

- Adjustable vibration frequency and intensity.

- Easy to clean and maintain.

Flow Chart

Feeding Conveying → Vibration Feeding → Frying

(In case of different kinds of product, please contact us for other special processes.)

Product Features

- It can reduce the temperature change during the frying process due to the quantitative feeding of the product, and the product can be evenly ripened to ensure stable quality.

Equipment Information Of Related Product

- Power: 90W.

- Optional single or two vibrators according to different kinds of product.

LAYOUT

Peripherals / Accessories

- Plastic Steel Conveyor Belt.

- Continuous Fryer.

- Related Products

Vibration Feeder

TsungHsing Food Machinery is a vibration feeder machine manufacturer and supplier. TsungHsing...

DetailsCentrifugal De-oiling Machine

TsungHsing Food Machinery is a continuous de-fatting machine manufacturer and supplier. Centrifugal...

DetailsContinuous Fine Filter

TsungHsing Food Machinery is a Continuous Fine Filter machine manufacturer and supplier. TsungHsing...

Details- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Vibration Feeder Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Vibration Feeder supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.