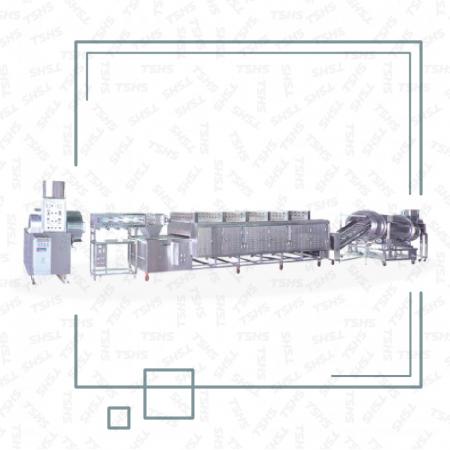

Grain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

Roasted Puffed Food Production line-CIP cleaning system (Thailand)

Food hygiene and safety regulations are becoming stricter. Collocation with the automatic Cleaning...