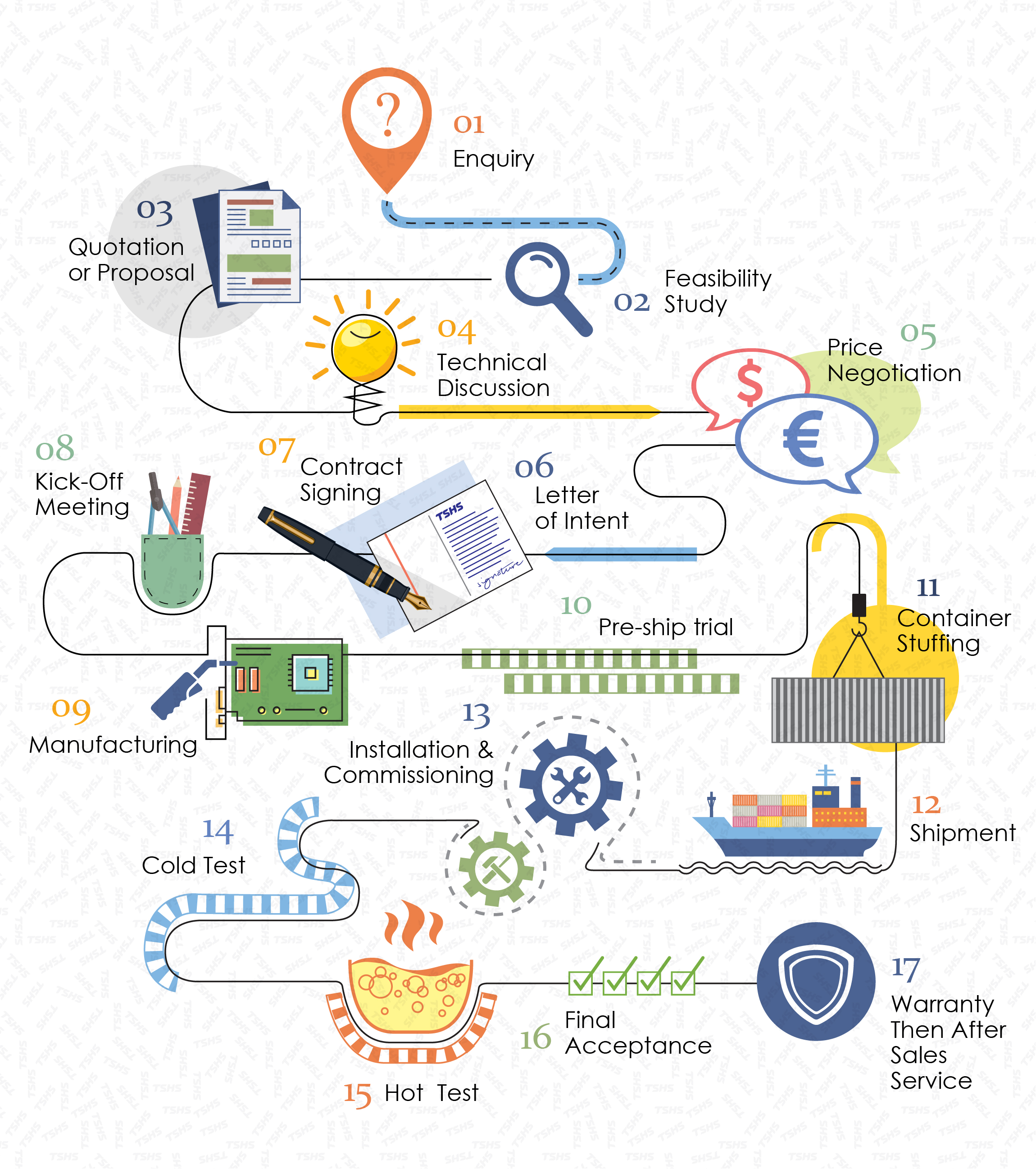

Service Process

(1). Customer Contact: Understand the customer's situation and establish a good relationship with them.

(2). Feasibility Analysis: Analyze and evaluate the product, whole plant planning, equipment configuration, customer budget, and give appropriate planning.

(3). Quote: Provide equipment quotation.

(4). Technical Discussion: Solve the problems faced by customers, such as: production, color, appearance...etc.

(5). Bargaining: Both parties confirm the price required for equipment purchase.

(6). Letter of Intent: Establish a letter of intent for the sale and purchase cooperation between the two parties.

(7). Contract: The cooperation letter of intent confirms that there is no problem, signing the contract, and begins to enter the equipment planning and design.

(8). Design Confirmation: Provide equipment flow chart and production line layout for customer confirmation.

(9). Production: Design and manufacture the equipment after confirming that there is no problem.

(10). Factory Testing: After the equipment is completed, the customer is invited to come to the actual raw material online test and quality process inspection in the factory.

(11). Delivery: After the test is completed, the delivery is made in accordance with the trade agreement.

(12). Transportation: Optional modes of transport just like shipping, air transportation, etc.

(13). Installation: The technical engineer will go to the customer site to quickly install and locate.

(14). Cold Commissioning: Carry out equipment idle running test to confirm voltage stability, gas pressure and heating effect.

(15). Hot Commissioning: After idle runnin, putting into the raw material production test and teaching the personnel how to use it.

(16). Acceptance: Final confirmation of the customer's last equipment, production samples, etc.

(17). Warranty: TSHS provides a one-year global warranty service.

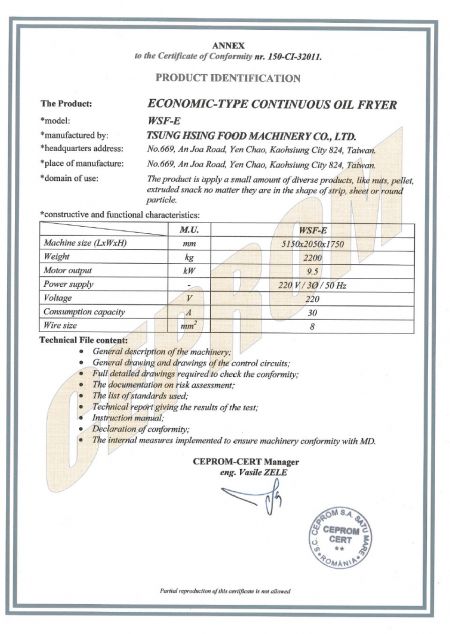

- CE

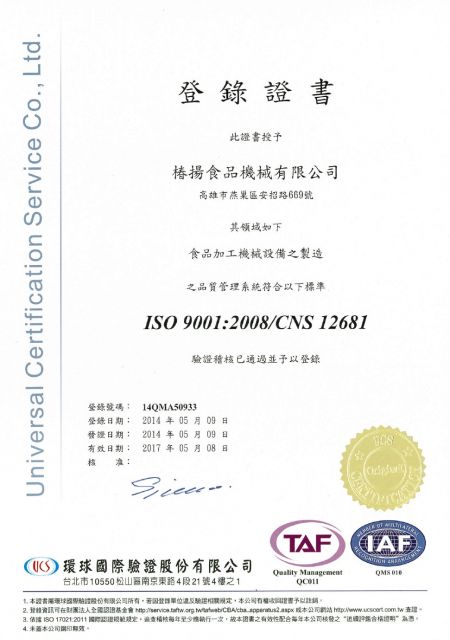

- ISO 9001

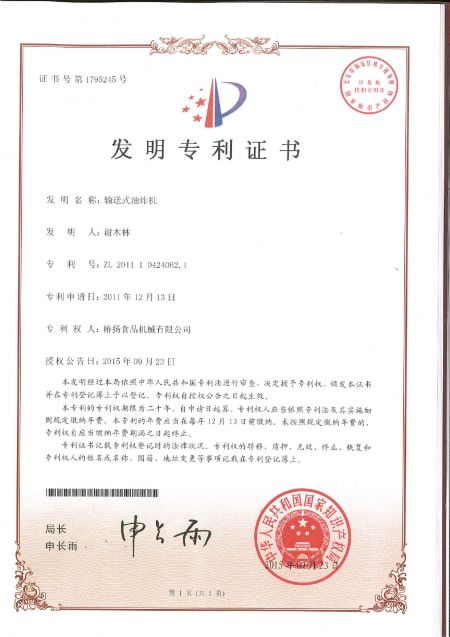

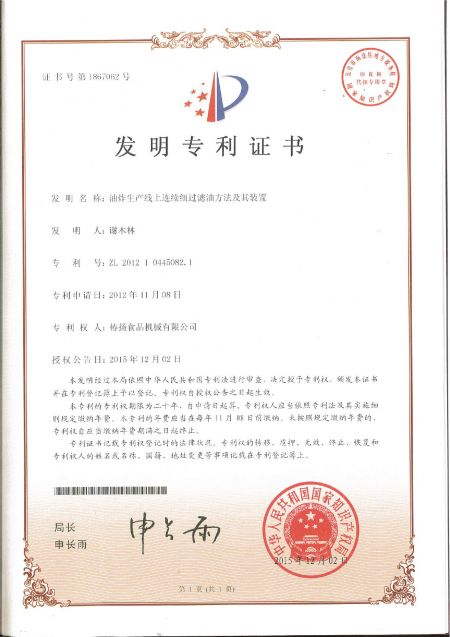

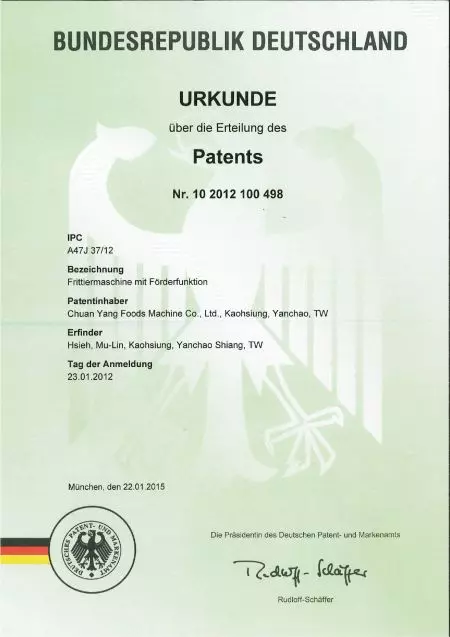

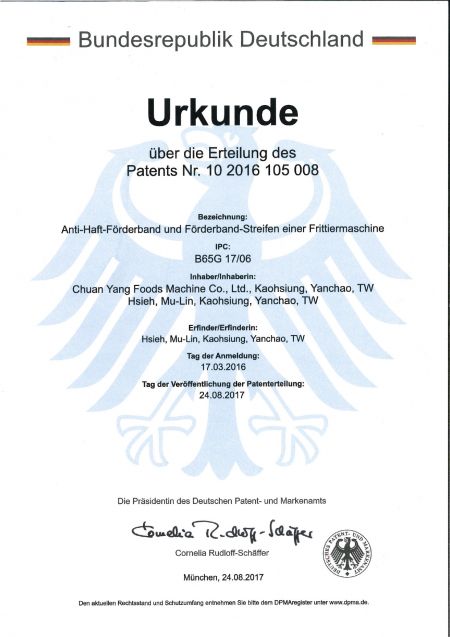

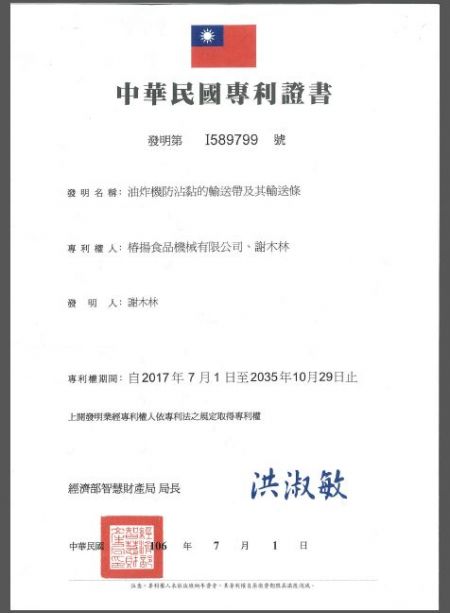

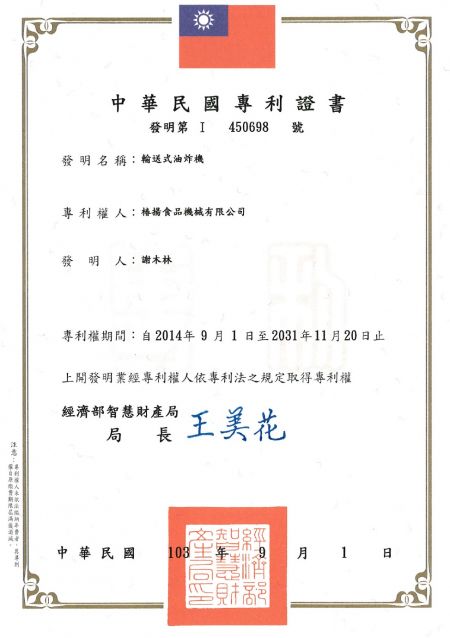

- Patent Certification

- Awards-1

- Awards-2

- D&B