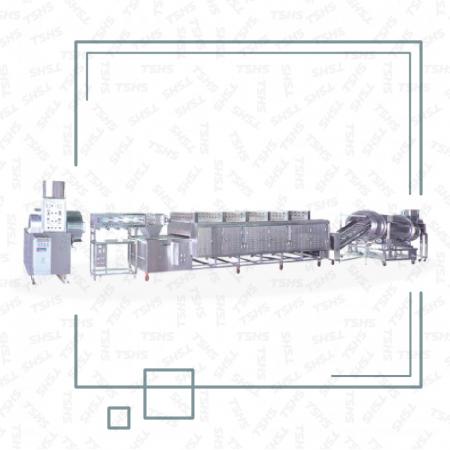

Roasted Puffed Food Production line-CIP cleaning system (Thailand)

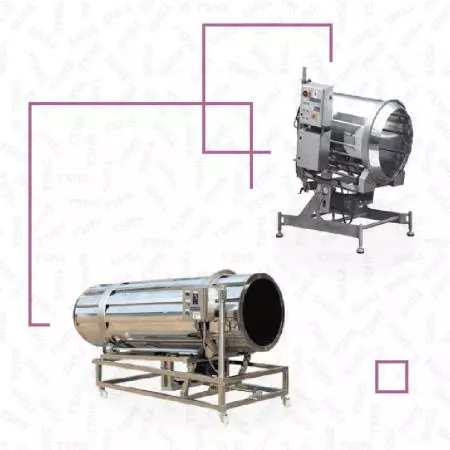

GRAIN PUFF PRODUCTION LINE- ROTARY SEASONING DRUM

Food hygiene and safety regulations are becoming stricter. Collocation with the automatic Cleaning In Place system(CIP) of Tsung Hsing conveyor fryer machine, it can solve the problem of customers’ old equipment that is not easy to clean. The machine TSHS provides can comply with the food hygiene and safety regulations, and it can also reduce the manpower requirements for equipment cleaning and effectively save labor costs.

How To Know Us?

So far Thailand is one of the main export trade country in TSHS. The customer found the rotary seasoning drum made by TSHS in local. Then we have the agent can supply to visit and show the reality equipment for the customer who interested in. Additionally, customer can realize more about how does it operate by testing the machine. Through the sales introduce with video patiently and deeply. Therefore they found we also have dryer machine. According to the advice from sales who recommended to combine the dryer machine with the seasoning drum. That makes the customers more interested in our product.

Why Choose Us

There were about six old production lines in the factory, so the customer had the idea of finding the new machine to replace the old equipment. In addition to increase the amount of original output, the regulations of Thai food are becoming more strict. Thus, it can be seen that they are paying more attention to the health and safety of food. In contrast, the original equipment had problems that are difficult to clean. To achieve the better machine cleaning results and food safety quality. TSHS has the CIP automatic cleaning system of leading R&D technology. Not only keep the equipment clean effectively and almost reduce the manpower. The food hygiene and equipment cleaned problem do not bother you anymore.

Trading Process And After-service

There are several test machine process during the trade process. The testing from small seasoning drum to large dryer. The most especially is, TSHS would provide the last testing before the shipment to make sure the machine gonna be okay. Testing machine before shipping that is no other peer companies have done. Besides, the buyer is more convinced with the sense of security and trust that the TSHS has given.

When installed the equipment in Thailand, it’s not easy to put the equipment to the designated location because of environment. By the active assistance of the sales and solve the problems by discussing, final it was successfully completed. TSHS will go to Thailand for customer service regularly, because of we regard Thailand as one of the main trade country. When you have not get understand yet, we provide the customer on site for teaching how to operate the machine. In case of operation problem or the demand for fault resolution immediately, we also provide you for teaching online. Through the latest technology of AR (Augmented Reality) which is combine the food machine industry. That is more convenient and accurate for customer service.

The Future

Combining with the latest technology to provide better customer service, TSHS will continue to advance and pursue the higher quality production process. In addition to assist you to solve all the problems and help your products become better than before. To create a peak result.

- Related Products

Grain Puff Production Line

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsRotary Seasoning Drum Equipment

TsungHsing Food Machinery is a rotary seasoning drum machine manufacturer and supplier. TsungHsing...

Details

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Roasted Puffed Food Production line-CIP cleaning system (Thailand) Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Roasted Puffed Food Production line-CIP cleaning system (Thailand) supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.